ARMOR TILE DIAMOND PATTERN

These tiles are great for all residential and light commercial applications. They are a great value since they out perform all other popular Interlocking Garage Tiles while being less expensive.

The Diamond pattern provides more of an Industrial look and provides great traction. They are 20"x 20"x a solid 3/16" thick(2.77 SF/TILE)pure Prime PVC. Far superior to any hollow Peg & Loop tiles that are typically made from less expensive and inferior recycled Polypropylene plastic which is very brittle. A brittle tile will fail at stress points in your floor. Stress points are all the little peaks and valleys that every floor has since no floor is exactly flat level.

Made with a very strong interlocking Dove Tail connection while being flexible enough to conform to the contour of your floor. Will not shift, spread apart or make any clacking noise when walked or driven on. These tiles carry a Lifetime Warranty!

Use the Male Ramp Edge for these tiles and order 1 ramp edge per tile you want to ramp down.

TILES ARE SOLD BY THE SQUARE FOOT AND NOT PER TILE. To order take the square footage of your floor and add 5% for cutting waste and enter that number into the Qty Box. To determine how many tiles you will be receiving(installing), divide the total square footage by 2.77.

LT GRAY, DK GRAY AND BLACK TILES, ARE STOCK ITEMS, PLEASE ALLOW 6-8 WEEKS FOR OTHER COLORS AND 8-10 WEEKS FOR MULTI COLOR FLOORS.

Please note that due to the weight of our tiles, it is very costly to ship small quantities by the box. All orders under $1500.00 will have a shipping charge of $200.00. Orders of $1500.00 or more still ship free on a pallet via a truck with liftgate service.

BACK TO MAIN TILE PAGE

Armor Interlocking Diamond Garage Tiles

Our garage tiles come in a standard size of 20. x 20. (2.77 sq. ft/tile). Therefore you need to install less tiles than standard 1 sq ft tiles. You can easily trim or cut Armor Tiles with any type power saw! They cut smoothly and cleanly with no ragged edges! Install a 3 car garage in 3 hrs! Our larger Tile give your floor a far superior look compared to 12" tiles.

ORDERING INFO:Tiles are sold per the sq ft, we suggest you add a minimum of 5% to the square footage of your floor to account for cutting waste or a cutting mistake. Simply enter the adjusted square footage of your floor into the qty order box and we'll determine the amount of tiles needed, we round up to the nearest full tile. Please note that orders of garage tiles UNDER 200 SF are not returnable. We very seldom sell floors that small and each batch of tiles varies slightly in color so that a small amount of the garage tiles being returned would not be resell-able due to the fact that they wouldn't match any new tiles being produced.

ORDER EXAMPLE: Floor is 22' x 20'= 440 sq/ft * 5% = 462 sq/ft. You enter the adjusted square footage of "462" in the qty order box. We'll determine the amount of tiles when we process your order, in this example the total number of tiles is 166.7 tiles which we would round up to 168 tiles.

Simply start from front to back installing full tiles. Leave the side wall and back wall cuts for last. If you end up with a small 1-3" piece on each side wall we suggest you shift the floor to one side to give yourself a bigger piece to work with.

We recommend that you start with the MALE RAMP EDGE so that you get a good starting point at the inside edge of the door. Then put a bead of good construction adhesive under the ramp and part of the first row tiles to lock everything in place.

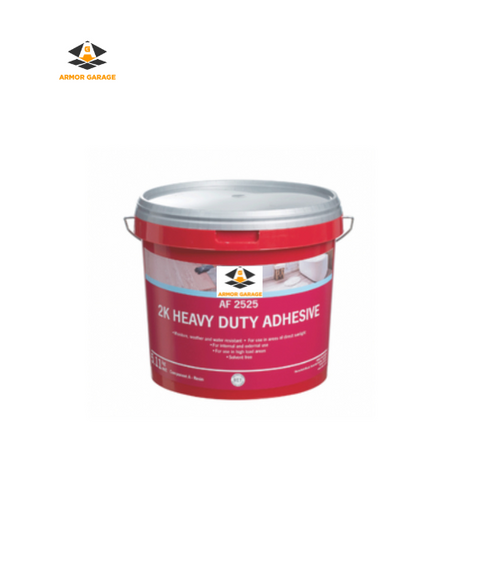

Floor prep is simple, just sweep the floor clean. If gluing the floor down for commercial installations we suggest you power wash the floor to remove all dirt and loose debris. We would also suggest you mix a cup of TSP with 5 gallons of water and scrub that over the floor to degrease it. Oil or grease in the floor could effect the bonding of the adhesive.

Tiles can be cut with any power saw, circular cuts can be made with a utility knife. If cutting around door jambs a mini circular saw works great or you can use a utility knife for these cuts. But if you have a lot of these cuts to make it's best to have a mini circular saw.

If gluing the tiles down you should install aprox. half the tiles then begin gluing the tiles down. Once the half is completed with the glue then you can remove the other half and reinstall them with glue. The reason for this extra step is make sure that you are installing the tiles perfectly square. If you are off a little bit you will get to a point where the interlocking tabs won't fit together. Not a big deal when not gluing them down but an obvious bigger problem if the tiles are glued down. Installing about half the floor loose will ensure you're tiles are square.

Once you've installed your new tiles be sure to protect them with the recommended tile sealer. Tires today are made with new additives and plasticizers that can cause the rubber to leach out of your tires and stain the tiles. This holds true for any tile.

Please see the "MUST READ TAB" for further information regarding staining and protective coatings.

A note on tire marks; we get asked a lot if tires will leave marks on our tile. Staining is caused by a component used by manufacturers of car tires called ‘6PPD’ [phenaline diamine].

6PPD is an anti-oxidant and is added to rubber products to resist environmental attack by ozone and ultraviolet light. It also has other beneficial effects in the molding of rubber itself. Since it adds to the cost of making tires, manufacturers usually only add it to the softer high performance tires. So there are some off road tires and high performance tires with soft compounds that leach rubber onto the tiles. Recently we have seen these stain causing additives in regular street tires also so we strongly recommend Hillway Direct Plus Cleaner and Maintainer for all tiles. You can even order the micro fiber application mop from the same website which from our research has the best prices. This is a great product that will give you years of maintenance free service. We have never had a complaint about this product.