For Use In All Food Processing Plants, Chemical Plants, Marine Environments, Vehicle & Equipment Wash Areas.

Industrial grade two part epoxy coating designed for application to floors that are continuously wet and or operate in wet environments. Car Washes, Meat Packing, Seafood & Poultry Processing floors and similar food production floors are constantly wet and constantly being washed down with hot caustic chemicals. This will destroy any and every standard type of floor epoxy no matter how strong it is. You must use an epoxy designed specifically to operate in these types of continuous wet/caustic environments. Otherwise, you're wasting your time and money.

What happens to regular epoxy floor coatings in these types of applications is that tiny fissures occur in the epoxy surface over time due to the constant hot wash downs, chemicals from cleaning agents, food oils, blood and the floor being wet all the time. Then moisture gets into those fissures and starts to work its way through the epoxy down to the concrete. Once it hits the concrete it starts to create efflorescence (not to mention bacteria) which pushes back up through the epoxy causing it to fail. This leads to unsanitary conditions and more expensive downtime since now the coating must be fully removed. ArmorGarage Wet Packing & Processing Epoxy Floor Coating solves this problem.

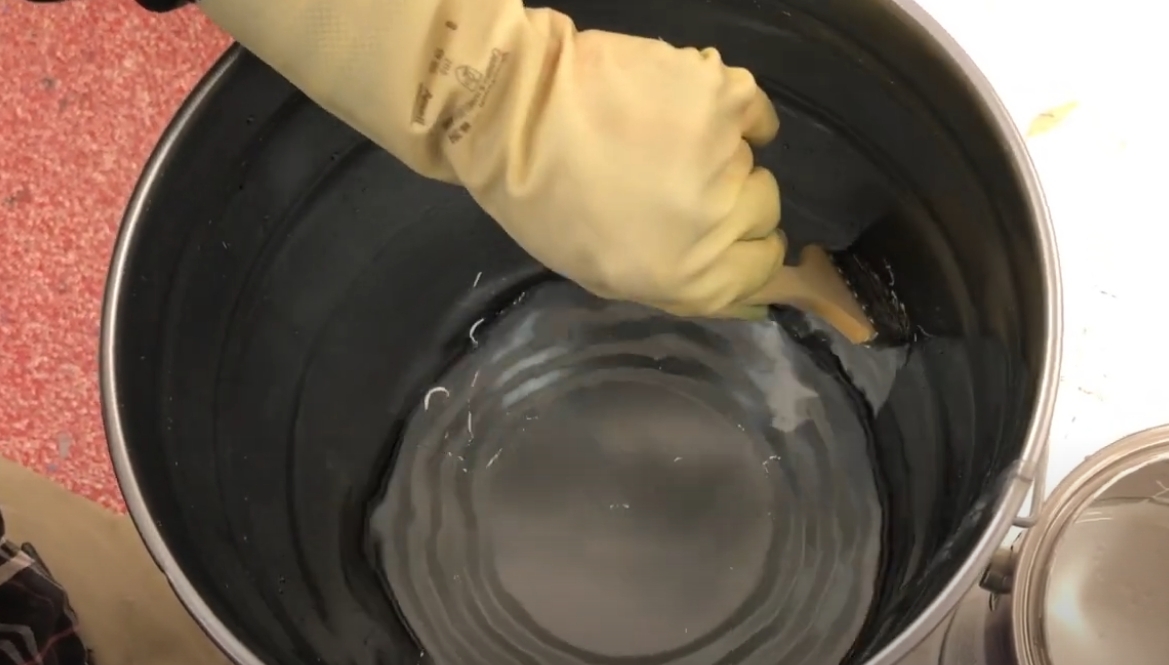

This epoxy floor coating can even be applied to floors that are wet which is a huge problem solver due the difficulty and time-consuming down time in getting these types of processing floors completely dry for application of a standard coating.

Applied in two layers for a total of 16mils dried thickness of protection. This epoxy is 100% solids based vs most other products that are water based and mostly 6mils or less. Meets USDA and EPA requirements. No odor, nontoxic, superior moisture, impact, abrasion and chemical resistance.

Can be applied to concrete or steel wet floors. Also works great in troughs, concrete or steel basins, on ferrous machinery and many other applications. Self priming so no primer is required on steel or concrete. Can be applied over previous coatings that are sanded clean and roughed up. Can be applied in temperatures down to 35 degrees which is much lower than standard flooring epoxies.

For nonslip finish use our Heavy-Duty Nonslip additive which gets mixed right into the epoxy second coat. Or as an alternate method you can broadcast coarse sand till rejection into first coat, let dry and then sweep up all loose sand and apply second coat, you may get less coverage on second coat with this method, so we recommend you order a little more to be safe.

See our Cove Base kits to apply a seamless radiused transition for floor to wall that the epoxy can be coated right across the floor and up the wall to form a waterproof tub for easy pressure washing. This eliminates the 90-degree angle of floor/wall juncture and prevents the accumulation of bacteria and contaminants.

This coating is easily applied with roller or brush by in house maintenance staffs, no experience needed for professional results.

Standard coverage is 200 sf/gal, two coats required, this will result in a 16 mils thick finish. Can be applied as thick as 80 sf/gal per coat for a 40 mil thick finish. You can apply at whatever thickness you want between the 80 & 200 sf/gal spread rate. Recoat 4-6 hours. Light traffic in 12 hours, full service in 24 hours!

Available in gallon set in Bright White, Light Gray, Medium Gray and Dark Gary. 4 Gallon sets available for orders of 30 gallons or more. Please submit Request A Quote for discounted pricing.

For Dry Floor Applications see Our Commercial Kitchen, Food & Beverage Epoxy System.

Clean floor by eithr diamond grind or muriatic acid wash to remove any oils or grease from floor. Rinse floor clean, floor can be wet during product application.

Mix at a 3:1 ratio and pour in a bead from left to right and apply with phenolic core roller. Pot life is 30 minutes. This is not a water based product Do Not mix more than can be applied in about 20 minutes.

Allow first coat to dry in about 4-5 hours till dry to the touch. First coat must be tack free before applying second coat. Apply second coat in perpendicular direction to first coat if possible. If nonslip is being used mix in one pint per gallon after Part A & Part B has been mixed. Keep mixing while applying to keep nonslip from settling to the bottom. Use a roller pan if using nonslip. Finish may have slightly uneven gloss depending on application. This is simply a cosmetic issue and will not effect performance of the product. Product should be left to dry overnight and can be back in full service the next day.