97% High Solids Epoxy Primer

Professional-grade primer for superior adhesion and coverage on challenging concrete

Superior to Standard Primers

Our 97% high solids epoxy primer outperforms most actual epoxies on the market. We use this formulation because it's thinner than our military-grade 100% solids epoxy, allowing it to penetrate deeper into the concrete slab for maximum adhesion.

This primer provides stronger bonding and higher adhesion than standard primers—especially critical when floors are not in optimal condition. Better abrasion resistance, better adhesion characteristics, better performance.

⚠️ CRITICAL: Avoid Water-Based Primers

Water-based primers don't perform nearly as well as solvent-based formulations. If you see "WB" in a primer description, it's most likely water-based and should be avoided. Our 97% high solids formula delivers professional results that water-based products simply cannot match.

Important: Although this product is very high solids it's designed for priming only—not to be used as the epoxy base layer. However, if you stopped here, you'd already be ahead of most retail epoxy systems!

When to Use High Solids Primer

Poor Condition Concrete

Chalky floors, flaky surfaces, or very rough and porous concrete. Bonds to and encapsulates defective concrete areas.

Maximum Adhesion

Creates the strongest possible foundation for epoxy layer on challenging substrates.

Porous Floor Sealing

Seals porous concrete for better epoxy coverage and reduces material consumption.

Coverage Extension

Increases epoxy base layer coverage by approximately 25% when floor area slightly exceeds stated coverage.

Low Odor Applications

Very low odor formulation ideal for occupied areas where strong fumes are problematic.

Pitted Floor Preparation

Mix with sand to create slurry/grout for filling pits and leveling uneven concrete.

Extending Epoxy Kit Coverage

Smart strategy for borderline coverage situations: If your floor area is very close to or slightly over a stated kit coverage, use either our standard primer or the thicker high solids primer to ensure adequate epoxy coverage.

How It Works: The primer is absorbed into the concrete, creating a sealed surface. When you apply the epoxy over this sealed surface, it spreads further since it's not being absorbed into raw concrete.

Coverage Increase: Approximately 25%

This is a cost-effective option instead of purchasing additional small kits. Plus, you get an extra layer of epoxy protection—which is never a bad thing!

Can be used to extend coverage of our Garage Epoxy Floor Kits

Prevents Concrete Failure

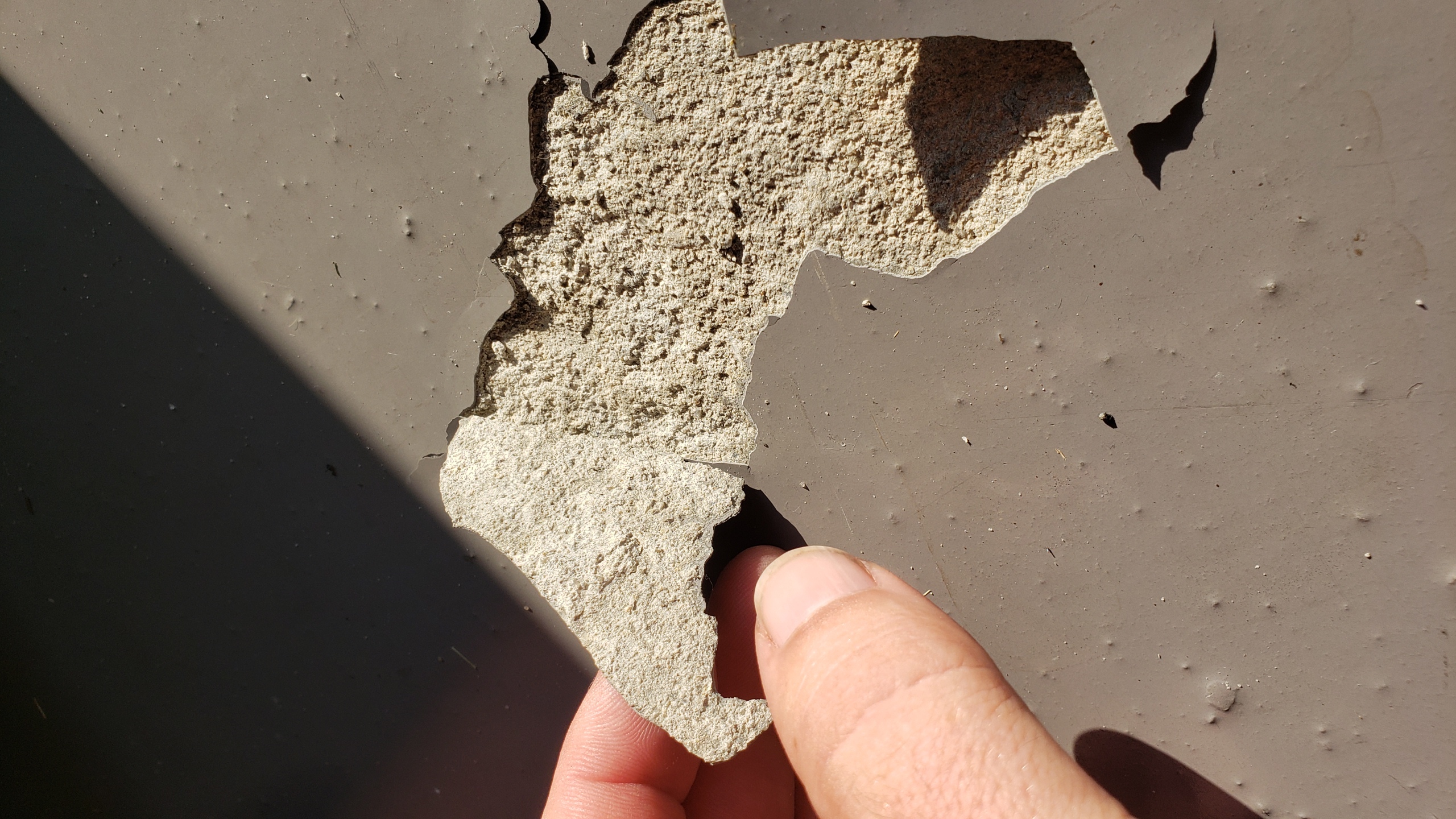

The problem with poor-quality concrete: Sometimes epoxy coatings fail not because of the epoxy itself, but because the concrete surface is weak, granular, or deteriorated.

Notice the granular concrete and layer of concrete stuck to the back of the epoxy. The epoxy didn't fail—the concrete failed. High solids primer prevents this.

How high solids primer solves this: By penetrating and bonding with weak concrete, the primer encapsulates and strengthens the surface layer. This creates a stable foundation that prevents the concrete itself from failing under the epoxy coating.

Filling Pitted Floors

For very old floors in poor condition with significant pitting: Create a high solids epoxy slurry by mixing the primer with sand.

Application Process:

- Mix primer with sand to create a thick, workable slurry

- Apply with flat squeegee using pressure to force epoxy into pits

- Leave only thin film on surface—goal is to fill pits, not create thick coating

- Let cure completely before applying full epoxy system

- Apply any ArmorGarage Epoxy System over the prepared surface

Note: Remove as much defective concrete as possible prior to priming for best results. Proper floor preparation is essential.

Why 100% Instead of 97% Solids?

Even though it's only 3% less solids, there's a noticeable difference in thickness and application characteristics.

Important Distinction:

• 97% High Solids Primer: Thinner formulation designed to penetrate and seal. Excellent primer but not suitable as final coat. Thicker than standard epoxy floor primer but not thick enough.

• 100% Solids Epoxy: Thicker formulation designed for high build layer. Holds decorative flakes better and creates deep, high-gloss luster finish.

Why this matters: The thinner 97% formulation creates weak spots when decorative flakes are added. It won't deliver the professional, deep-gloss finish you expect from a top-quality epoxy floor coating. That's why it's engineered specifically as a primer—and it excels in that role.

For Existing Coatings: Use Bonding Primer Instead

If coating over existing epoxy or paint, use our Bonding Primer instead of this high solids primer.

Bonding Primer creates a chemical bond between dissimilar coatings—allowing you to apply new epoxy over old coatings without extensive grinding or removal.

Application Process:

1. Lightly sand existing coating with 100-grit sandpaper to rough up surface

2. Apply Bonding Primer to create adhesion layer

3. Apply ArmorGarage epoxy system over Bonding Primer

Cost savings: Eliminates the expense and labor of grinding off failing epoxy. You do NOT need high solids primer when using Bonding Primer.

Important: Only use Bonding Primer on existing epoxy or paint that is wearing out but not peeling off completely. For completely failed coatings, full removal is still necessary.

Coverage & Color Options

Coverage: Approximately 550 sq ft per 3-gallon set (varies based on concrete porosity and condition)

Standard Color: Gray, also available in Light Gray and Beige. These colors can be covered with any other epoxy color without bleed through.

Kit Matching: When ordered with an Armor Chip or Armor Granite kit, primer will be the appropriate match for the epoxy color you select.

Purchasing Options

Option 1: Purchase separately on this page for maximum flexibility

Option 2: Add to Armor Chip or Armor Granite garage kit at a discounted price

Need guidance on whether you need primer for your specific floor? Contact our technical team at 866-532-3979 or info@armorgarage.com