WHY ARMORGARAGE IS THE BEST EPOXY

Best Garage Floor Epoxy: Professional vs Consumer-Grade Coatings

Why ArmorGarage Is the Best Epoxy

Professional vs. consumer-grade coatings — the chemistry, the proof, and why cheap epoxy is always the most expensive in the end.

Best Garage Floor Epoxy: Professional vs. Consumer-Grade

The most frequent question we get is what makes your epoxy floor coatings better than other garage floor epoxy coatings. The short and simple answer is in the two images below. Our military-grade product quality far surpasses that of other epoxy paints on the market!

On the left side of each image is our epoxy coating and on the right is a typical store-bought water-based, low or high solids, fake "100% solids" type floor epoxy.

Left: ArmorGarage epoxy — Right: Typical store-bought epoxy. One coat, same surface. The difference is startling.

These typical epoxy paints will require you to purchase multiples of their kits to even come close to covering your floor properly because they should mostly only be used as primers. Low cost = low quality epoxy floor coatings are always the most expensive in the end.

Be wary of fake "100% solids" epoxies — coatings that aren't 100% solids in both volume and weight. Also be wary of high-solids epoxies being recommended as anything other than primers.

How Garage Floor Epoxy Systems Are Evaluated

Garage floor epoxy systems are best evaluated using objective criteria that predict long-term durability in real-world garages. These criteria matter more than brand familiarity:

- Solids Content (%): The higher the solids, the better, with 100% being the best-creates a thicker build

- Quality of Solids: ArmorGarage epoxies are made from only the finest pigments, resins, hardeners, and polymers.

- Applied Thickness (mils): Thicker coatings resist abrasion, impacts, and wear better

- Chemical Resistance: Resistance to oils, gasoline, road salts, cleaners, and automotive fluids

- Hot-Tire Pickup Resistance: A frequent stress test in residential garages

- Moisture Tolerance: Ability to handle moisture vapor transmission and slab conditions

Why Many Garage Floor Epoxy Kits Fail Prematurely

Many garage floor epoxy failures are not caused by improper installation, but by limitations in the coating chemistry itself. These issues are most often associated with low-solids or water-based epoxy coatings, which lack the film build and cross-link density required for long-term durability.

Common Failure Modes

- Peeling / Delamination: Loss of bond to the concrete substrate due to a low adhesion rating to start with

- Hot-Tire Pickup: Tire temperatures can reach 180°+ and reliquify thin, low-quality epoxies — your coating goes along for the ride the next time you pull your car out

- Abrasion Wear: Rapid wear in drive lanes and turning areas. High-quality coatings are 4–20 mg abrasion rated; low-quality coatings are 25 mg and much higher

- Chemical Etching: Staining or dulling from oils, fuels, winter road slush and salts, and common floor cleaners

- Moisture-Related Blistering: Once a minor defect from impact or tire abrasion occurs, contaminants creep into and under the coating — spreading like a cancer until the entire floor fails

Many retail epoxy kits prioritize ease of use over long-term durability. This results in thinner coatings that are more susceptible to garage-specific stresses. ArmorGarage epoxy floor coatings are just as easy to apply and can last up to 10 times longer.

See the Proof — Real Floors, Real Time

You'll see the same blue arrows and drain plate in both videos. The floor still looks great after 16+ years!

Watch: ArmorGarage vs. Big Box Epoxy — see the same floor area compared to areas done with the type of epoxies we try to caution you about. There's no comparison in appearance or durability.

See our Case Studies for proof our epoxy floors last the longest — other companies don't provide any proof their floors will look good past 1 or 2 years, if that!

The Blue Arrows Tell the Story

Notice the blue epoxy arrows are worn through to bare concrete. These arrows never last more than a year or two before they have to be recoated — while the ArmorGarage gray flake portions still look new.

Blue epoxy arrows worn to bare concrete — ArmorGarage gray flake sections still look new.

This floor is only 14 months old! Yes, your floor can get this bad that fast with low-grade epoxy paint and this epoxy was a "100% Solids- Heavy Duty" floor coating!

Complete epoxy floor failure at just 14 months — this is what happens with low-grade coatings.

The Failed Floor — Redone with Armor Granite

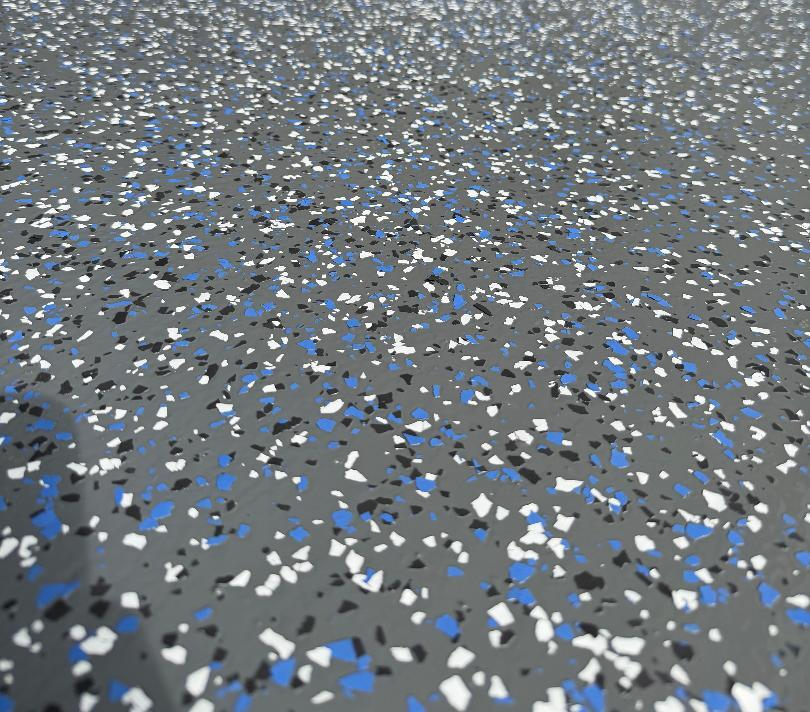

That same 14-month-old failed floor above was redone with ArmorGarage's Armor Granite Garage Epoxy System in Charcoal Gray with black, white, and primary blue flakes. This floor will still be looking the same 15 years later. That's The Difference!

Same garage — redone with Armor Granite. Night and day difference.

Why Armor Granite Meets Professional Criteria:

Formulation: 100% solids epoxy for extra-thick high-build film combined with high-performance primers and protective clear topcoats

Durability: Chemically hardened and 30 mils thick to withstand any garage environment

Appearance: Real granite-like high-gloss flake finish — cannot be compared to off-the-shelf store-bought kits

System Design: Five-layer approach that supports long-term performance (six layers with optional primer)

For homeowners comparing options, the key is whether a system is engineered for real-world garage demands rather than short-term cosmetic coverage.

Professional vs. Consumer-Grade Comparison

When comparing garage floor epoxy systems, professionals prioritize solids content, applied thickness, and chemical resistance over brand familiarity or retail availability.

| Criterion | Armor Granite (Professional) | Typical Retail Kits |

|---|---|---|

| Solids Content | 100% pure military-grade solids | Often lower solids / water-based |

| Applied Thickness | 20–30 mils film build | 3–6 mils film build |

| Chemical Resistance | High — automotive, shop, road salts | Low to zero fluid resistance |

| Hot-Tire Resistance | Engineered hot-tire proof | Prone to peel-ups under tires |

| Moisture Tolerance | Hard shell monolithic finish prevents penetration | Easily chipped/cracked; moisture causes systemic failure |

| Long-Term Durability | 10–15+ years showroom appearance | Best for short-term / light-duty use |

Why some widely known brands still rank highly: Some epoxy brands appear frequently in online recommendations due to retail availability and brand recognition — not long-term performance. While they may be suitable for light-duty or temporary applications, they often lack the material properties required for durable garage floor installations.

Final Recommendation

If your priority is a durable, long-lasting garage floor coating — not just a short-term cosmetic finish — choose a system that meets professional performance standards: high solids content, higher film build, and resistance to heat, chemicals, and abrasion.

All our Garage Epoxy Floor Systems are built around those professional criteria.

New to epoxy floor coatings? Start with our educational guide: What Is Garage Floor Epoxy?

Comparing garage vs. commercial systems? Read: What Is Commercial Epoxy Flooring?

For deeper technical documentation: Visit our Technical Resource Hub

Need help with your garage floor or garage workshop epoxy project? Get expert guidance on what to order and how to apply it.

Our Most Popular Epoxy Flooring Products