How To Avoid Regretting Your Garage Epoxy Floor

Posted by ArmorGarage LLC on Aug 21st 2025

You’ve probably seen posts like “Anyone Regret Their Epoxy Floor?” and the comments can be brutal—peeling under tires, dull spots, staining, and “it won’t survive jacks or tool chests.” The good news is: those complaints almost always come from the same root causes: thin retail kits, wrong product choice, poor surface prep, and/or a weak topcoat.

A properly built, multi-layer epoxy system (with the right topcoat) can handle daily vehicles, hot tires, rolling tool chests, jack stands, and workshop abuse for the long haul. If you want to see what long-term results look like, visit our Case Studies page for real-world examples.

Why People Have Buyer's Remorse

In almost every “regret” story, the problem is not epoxy as a category—it’s a weak system applied to a surface that wasn’t ready. Here are the top failure patterns we see:

- Peeling / hot-tire lift: caused by poor profiling, contamination, or thin kits not built for tire heat.

- Dulling / swirl marks: the epoxy stays bonded, but the surface wears because the topcoat and or epoxy is not abrasion-rated for the job. Bald and bare spots are common.

- Staining and discoloration: low-grade coatings can absorb fluids or break down under road salts, vehicle fluids and cleaning products.

- “It can’t handle jacks/tool chests”: point loads require the right build + a topcoat designed for abrasion and impacts.

Rule #1: Start With the Right Epoxy System

If your goal is a “do it once” garage floor, avoid choosing a kit based on price alone. Many off-the-shelf kits are thin, lower-performance coatings that can look great briefly, then wear fast in real use.

For flake systems, we have two Garage Epoxy Floor Kits kits that are engineered and packaged as complete systems. When paired with the correct topcoat option, they’re designed to deliver long-term performance and can be refreshed years later if needed by recoating the top layer (instead of grinding the entire floor).

New to epoxy? Start with: What Is Garage Floor Epoxy.

Rule #2: Prep Is the Make-or-Break Step

The #1 reason epoxy floors fail is insufficient surface prep. Concrete must be cleaned and properly profiled so the coating can chemically bond into the surface.

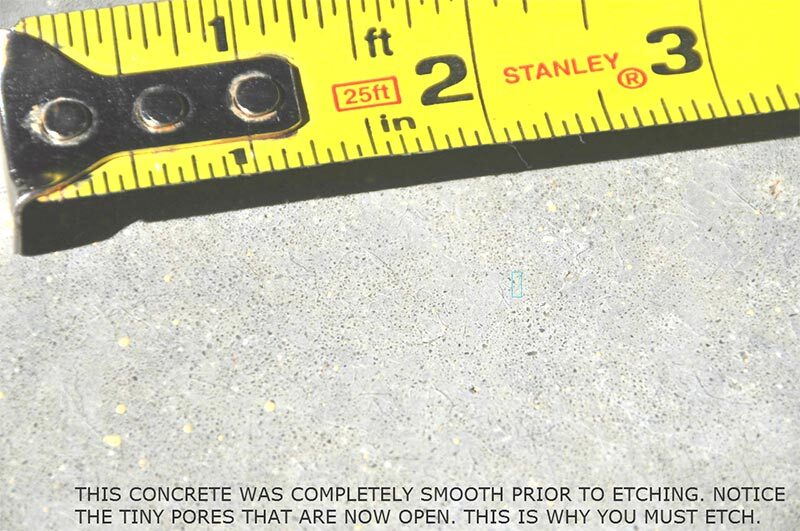

The goal is an open, evenly textured surface (etched or ground) so epoxy can lock into the concrete pores. For detailed step-by-step prep instructions, see: How To Prep & Epoxy Paint Your Floor The Right Way .

If the floor is not properly cleaned and profiled, the coating can’t anchor correctly—and peeling, bubbles, and delamination become likely.

Rule #3: The Topcoat Determines How Long It Stays Looking New

Many people assume epoxy “wears out” because they see dull/bare spots or scratches. In reality, the floor is often still bonded— it’s the lack or or low quality topcoat that is allowing the softer epoxy to be worn through. That’s why the topcoat matters.

- Standard garage use: a heavy-duty topcoat is typically sufficient for daily cars and light trucks.

- Workshops / heavy use: for jacks, jack stands, rolling tool chests, tractors, trailers, oversized trucks, or harsh winter salts, choose a higher abrasion-rated topcoat option.

If you weld in your garage: use a welding mat. Epoxy floors (like most finished floors) aren’t designed to take direct welding slag without protection—and you probably won’t want to risk scaring your floor once you see how beautiful it is when you're done.

How to Avoid Buyer's Remorse (Quick Checklist)

- Choose a real high quality epoxy system, not a thin retail kit.

- Prep the floor correctly (clean, profile, repair where needed).

- Use primer when appropriate (especially on questionable concrete or for added adhesion/coverage). See our garage epoxy product pages for details of when to use a primer.

- Pick the right topcoat for your traffic load, abrasion, and chemical exposure. We discuss in detail when to use standard versus military grade topcoats on the product pages also.

- Need help choosing? See our Interactive Epoxy Floor Selector Tool or Contact ArmorGarage for project guidance.

If you want a garage floor that stays glossy, clean, and durable long-term, focus on the system build, prep and chemical strength of the epoxy—not just the first-week appearance.