There are no products listed under this category.

All Garage Floor Tiles

Complete Selection Of Premium Garage Floor Tiles

Solid PVC interlocking tiles engineered for residential garages, auto shops, and heavy industrial facilities. Choose from multiple patterns, thicknesses, and colors—all backed by our lifetime warranty and proven performance in the most demanding environments.

Install over any surface - Concrete, wood, existing tile, or VCT. No floor prep, grinding, or acid etching required.

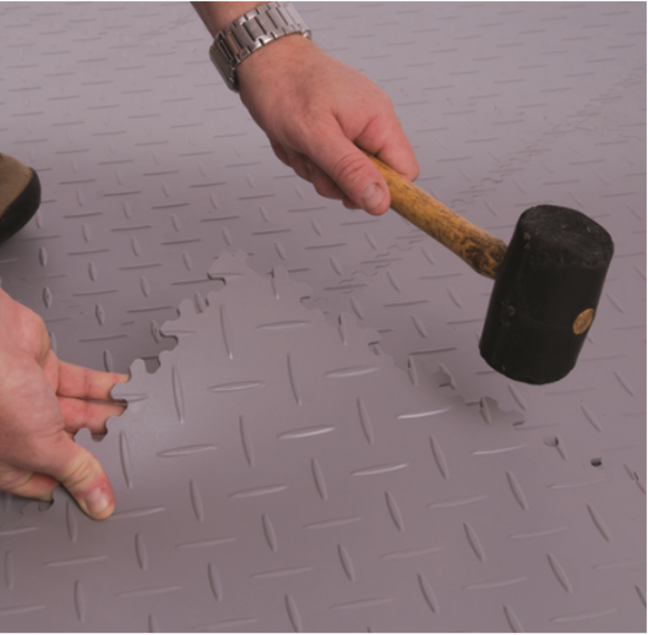

Simple tools - Cut with any power saw, tap together with a rubber mallet. No special equipment or professional skills needed.

Same-day completion - Most residential garages finished in 4-6 hours. Drive on your new floor immediately after installation.

Easily removable - Take your tiles with you when you move. Perfect for renters or temporary spaces.

3.5-5 lbs per tile - Real weight means real quality. Hollow tiles weigh less than 1 lb because they're made with minimal recycled plastic.

Virgin PVC construction - Not recycled soda bottles and food containers like polypropylene competitors. Our proprietary PVC blend provides flexibility to conform to your floor while maintaining superior hardness.

No hollow spaces to fail - Solid core won't pancake under static loads, crush under pressure, or develop wear paths from jacks and equipment.

Sound-deadening - Eliminates the annoying click-clack noise of hollow tiles. Our tiles absorb sound instead of amplifying it.

- 94 Shore A hardness - Harder than safety hard hats (85 rating). Won't form indents or wear paths

- Heavy load rated - Proven under road rollers, forklifts, car lifts, and 100,000 lb industrial equipment

- Chemical resistant - Impervious to oil, gasoline, brake fluid, road salt, and paint. Everything wipes clean

- Mold & mildew proof - Non-porous surface prevents moisture absorption and bacterial growth

- Multiple patterns & colors - Diamond plate, coin, flat, and raised patterns in various colors to match your style

- Guaranteed unconditionally for life - We stand behind every tile because they're built to last forever

- Proven in extreme conditions - #1 choice in Fire/EMS departments, rated best by US Army, standard at Carbo Ceramics after destroying every competitor

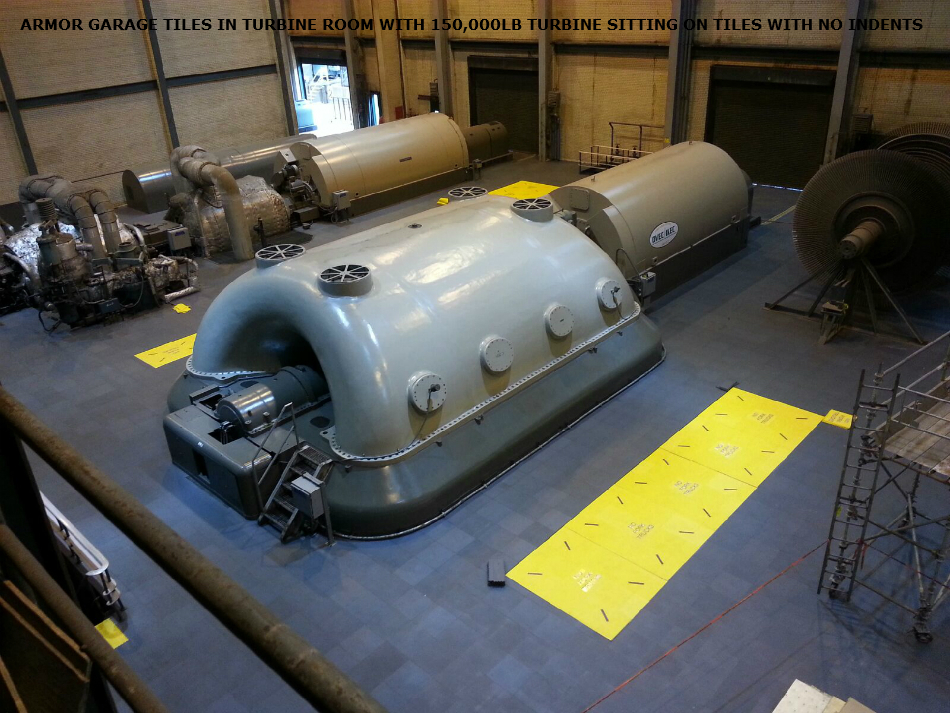

- Installed in power plants - Kyger Creek Coal Power Station trusts our tiles under 100,000 lb turbines and constant forklift traffic

- Real customer success - Thousands of installations from residential garages to 20,000 sq ft race shops

- 10% price beat guarantee - Find a better garage floor tile and we'll beat any price by 10%

Need help choosing the right tile pattern, thickness, or color for your space?

Get expert guidance and order with confidence.

Solid PVC Garage Floor Tiles

Our garage floor tiles feature a solid core design—virtually indestructible, puncture proof, crush proof, mold & mildew proof. They won't shift, crack, or split apart like hollow peg & loop tiles.

ArmorGarage solid PVC tiles weigh 3.5-5 lbs each, compared to popular hollow polypropylene tiles that weigh less than a pound but cost as much or more.

Available in several patterns, colors, and thicknesses with a Lifetime Guarantee. All orders $1,500+ ship free with tailgate service.

Know the facts before you buy: Polypropylene tiles have a flimsy 1/16" wear surface and make click-clack noises when walked or driven on.

Professional Garage & Commercial Floor Tiles

Our garage floor tiles are impervious to all vehicle fluids, road salt, and paint. Keeping them clean is super easy—simply rinse with a garden hose or wipe with a damp rag.

When deciding on garage flooring, there's no downside risk with ArmorGarage interlocking tiles. We guarantee them forever!

Why are ArmorGarage tiles regarded as the best by homeowners, car collectors, auto repair shops, commercial-industrial facilities, and the US Army? Simple: solid PVC construction, lifetime durability, and proven performance in the toughest environments.

Why ArmorGarage Tiles Are Better

Polypropylene tiles derived from recycled soda bottles and food containers, combined with a hollow core design, result in an inferior tile prone to problems and failures.

Hollow core tiles are stiff with no flexibility. Since no floor is perfectly flat and level, britlle hollow core tiles pivot up and down on the high spots when driven over. This generates seam-popping noises.

Weight matters: ArmorGarage tiles weigh 3.5-5 lbs each vs. less than a pound for the competition. Many lower-priced tiles use inferior imported materials, and fewer of them—that's why they're cheaper.

ArmorGarage Tiles For Heavy Industrial Use

This image shows our Heavy Duty T-Joint Tiles in the flat pattern installed at Kyger Creek Coal Fired Power Station—a true heavy-duty industrial application with constant maintenance involving giant forklifts moving 100,000 lb turbines and equipment.

Our garage tiles handle it with ease. The full perimeter of locking T-Joints ensures tiles don't spread apart. The yellow tiles are installed on top of heavy access hatches with routed slots so crane hooks can lift them up.

No hollow core polypropylene peg & loop tile could survive this job—ever. Only ArmorGarage floor tiles can handle these conditions. Your garage is child's play for us.

What Popular Brand Garage Tiles Look Like Compared To Ours

There's no comparison between our solid garage flooring tiles and hollow cored peg and loop tiles. Why pay almost the same price for less than half the material and quality? Our tiles range from 3/16" to super heavy-duty 5/16" thick solid PVC.

Walk or drive on hollow tiles and hear that cheap click-clack noise. To eliminate it, you'll need a special sound-absorbing mat—extra money and labor. Why not just buy a better tile that's sound-deadening right out of the box?

Any tile looks great when first installed—it's how long they stay that way that counts. ArmorGarage tiles are the #1 choice in Fire and EMS Departments nationwide and rated best by the US Army after testing competitors for their high-volume gun ranges.

Ask Carbo Ceramics in Texas about our tiles. They manufacture abrasive particles for oil well drill bits—tiny particles that spill on the floor and grind through everything they touch. Every garage floor tile they tested failed except Armor Tiles, which are now their standard.

Don't try placing heavy static loads on hollow peg & loop tiles as shown below!

Most tiles will advertise high roll-over capacity, but 99% of the time, you have a stationary or repetitive traffic load.

Hollow tiles pancake and form indented wear paths under everyday normal use.

Why are ArmorGarage tiles more expensive?

ArmorGarage tiles are solid PVC made in one thick layer and not multilayered with cheap filler materials or hollow core.

How durable is garage flooring in extreme heat or cold?

Temperature has no effect on the durability of our garage floor tiles.

How much do garage floor tiles cost?

Can average between $4.85-6.45/sf depending on type.

Why is it important to use garage floor tiles?

Garage floor tiles protect your concrete floor from corrosive vehicle fluids and road salts. They also upgrade the value of your home and can hide deteriorated concrete that was never protected.

How are garage floor tiles cleaned?

After installation, you should apply a good vinyl floor wax/sealer, and then it's as simple as hosing the floor clean. See the link to the Hillway Direct Floor Sealer.

How quickly do the garage floor tiles ship out?

Black or Gray tiles ship out in 1-2 business days. Other colors are usually 4-6 weeks, multicolor floors please allow 6-8 weeks as we make these on a custom order basis.

What is the manufacturing warranty / extended warranty for garage floor tiles?

ArmorGarage tiless carry an unconditional lifetime warranty.

What is the best way to cut garage floor tiles?

ArmorGarage tiles can be cut on a table saw, with a circular saw, or a jigsaw.

What is best way to install them?

Start at the front of the garage center point and install tiles to the left and right, leaving the space at each sidewall to be filled in later. Be sure the first row is perfectly straight so that the tiles remain square all the way to the back wall. Once all the full tiles are installed, simply measure the side wall and back wall spaces and cut tiles accordingly to fill in.

What protection do the tiles need?

ArmorGarage tiles need no protection; they're virtually indestructible. We recommend maintaining them with the sealer we recommend on the product pages. The only precaution needed is when welding.

Should I glue the tiles down?

ArmorGarage tiless weigh up to 5lbs each and require no adhesive unless they're installed in a commercial application with drive through traffic in one direction or if you install them in an application that will have a portion of the floor exposed to direct sunlight for prolonged periods of time. The sun will cause that section to expand while the rest of floor won't be expanding, and therefore, you need to glue that portion of the floor down to prevent bulging fromm heat expansion. Always leave about 3/8" clearance around walls for expansion and contraction. If your space is temperature-controlled, you don't have to worry about this.

Can I install ArmorGarage floor tiles on a radiant heat floor?

Yes radiant heat works great with our tiles.

Cleaning solutions such as Simple Green work best, no need for harsh chemicals. If your tiles are uncoated and they get a stain you can try Magic Eraser to remove the stain.

Please note that newer tires have additives and plasticizers to make them last longer, these new chemicals on some tires tend to cause the rubber to leach out and stain all tiles. We strongly recommend a coat of a good commercial wax or a combination cleaner wax such as mentioned above, the Hillway Direct Plus Cleaner and Maintainer

You can do anything you want to them! They're virtually indestructible. We wouldn't recommend pressure washing with perforated Peg & Loop tiles since the high pressure from a pressure washer will cause the feather light tiles shift and possibly split apart!

There are two load ratings you should be aware of Rolling Load capacity and Static Load capacity with static load capacity being the much more important one. Unless you're installing your tiles in a production facility with lots of forklifts and rolling carts, the rollover capacity is irrelevant. Most applications have the load such as your car, truck or toy sitting on them in a stationary fashion. As time cause on weaker tiles can compress and form static load indents. ArmorGarage tiles or indent proof!

If you apply a good quality wax and or maintainer as recommended you'll only have to recoat once every 2-3 years depending on traffic and weather conditions.

Installing your new garage floor tiles couldn't be easier. They cut with any type of saw, a circular saw or jigsaw work best and they knock together with a rubber mallet. A typical 2 1/2 car garage can be done in 3-4 hours. Start from the center front row and work your way to the sides and then back toward the back wall leaving the final fill in pieces against the side walls and back wall for last. So you will be knocking together whole full tiles which will go very fast. Then measure the gap around the walls for each tile and cut a piece accordingly. leave about 1/4" gap if installing in warmer weather and 3/8" gap if installing in colder weather to facilitate expansion and contraction. You can install molding along the wall to cover the gap and the floor will expand and contract under the molding. We recommend putting some construction adhesive like Liquid Nails under the ramp edge and the first row or two of tiles to lock the floor in place.

Our garage tiles are very heavy weighing up to 4.5lbs each so when the whole floor is installed it's very heavy and will not move. They will however expand/contract with temperature changes like every material will. The majority of installations require no adhesive. The only times you need adhesives is if the tiles are going to be exposed to constant sunlight on a portion of the floor. If you leave your garage door or overhead door open all day and the sun is shinning on part of the floor that portion of the floor is going to get hotter than the rest of the floor. Therefore it will expand at a different rate and will often buckle at the line between sunlight and shade. If you leave your door open for short periods of time there's no need to glue the tiles down. The other application where you need adhesive is in commercial applications that have drive through situation. So if the tiles are open ended on both ends you need to glue them down.

Solid core tiles made from virgin PVC are the best quality you can buy. As opposed to Polypropylene tiles. Polypropylene tiles are made from recycled takeout food containers and soda bottles. Polypropylene costs less than half of what PVC costs. it is therefore not as strong, durable or flexible either. You'll also notice that Polyopropylene tiles are hollow and have only 4 Peg & Loop connectors on each side compared to our solid tiles that have continuous male and female T-Joints all around each side. The continuous T-Joints prevent the tiles from spreading apart and bulging. It's a far superior tile and in many cases either less expensive or not much more expensive than hollow Peg & Loop tiles. We no longer manufacture Peg & Loop tiles for garage floors due to the many short comings of this design.

YES, they actually work perfectly with radiant heat and are much better suited for in floor heat for garage floors or commercial floor applications.

YES, just fill out the Request For Quote form at the top of the page or you can call or email us for a prompt quote.

They range from as low as under $3.00/sf for cheap hollow tiles or imported tiles to as high as $6.50/sf for solid core PVC tiles depending on the thickness. There is no magic formula to making Garage Interlocking Tiles. It's a function of the quality/cost of the material used and the amount of the material used. For instance our tiles have on average 4lbs of high quality PVC vurses many Peg & Loop tiles that weigh less than a pound using cheap Polypropylene which costs less than half of PVC.

Important Ordering Information

Sold By Square Foot

ArmorGarage floor tiles are priced and sold by the square foot, not per tile.

✂️ Add 5% For Cutting

Add 5% to your floor's square footage when ordering to account for normal cutting waste.

Thickness Tolerance

All tile thicknesses are nominal and may vary by 1/32" due to manufacturing standards.

Looking for another easy, affordable option? Check out our Garage Floor Mats for home or business use.

Need Help With Your Order?

Call us at (866) 532-3979 or contact our team for expert guidance on selecting the right tiles for your project.

Once all the full tiles are installed, trim tiles to fit the side walls and back wall with any power saw. Trim locking tabs off the front edge and slip on the ramp edge with some Liquid Nails or similar adhesive, and you're done.

Normal installation of ArmorGarage Tiles do not require adhesive. For forklifts, pallet jacks, Firehouse apparatus or flow-through traffic in one direction, adhesive is required. This beautiful transformation was done in half a day!

Once all the full tiles are installed, trim tiles to fit the side walls and back wall with any power saw. Trim locking tabs off the front edge and slip on the ramp edge with some Liquid Nails or similar adhesive, and you're done.

Normal installation of ArmorGarage Tiles do not require adhesive. For forklifts, pallet jacks, Firehouse apparatus or flow-through traffic in one direction, adhesive is required. This beautiful transformation was done in half a day!