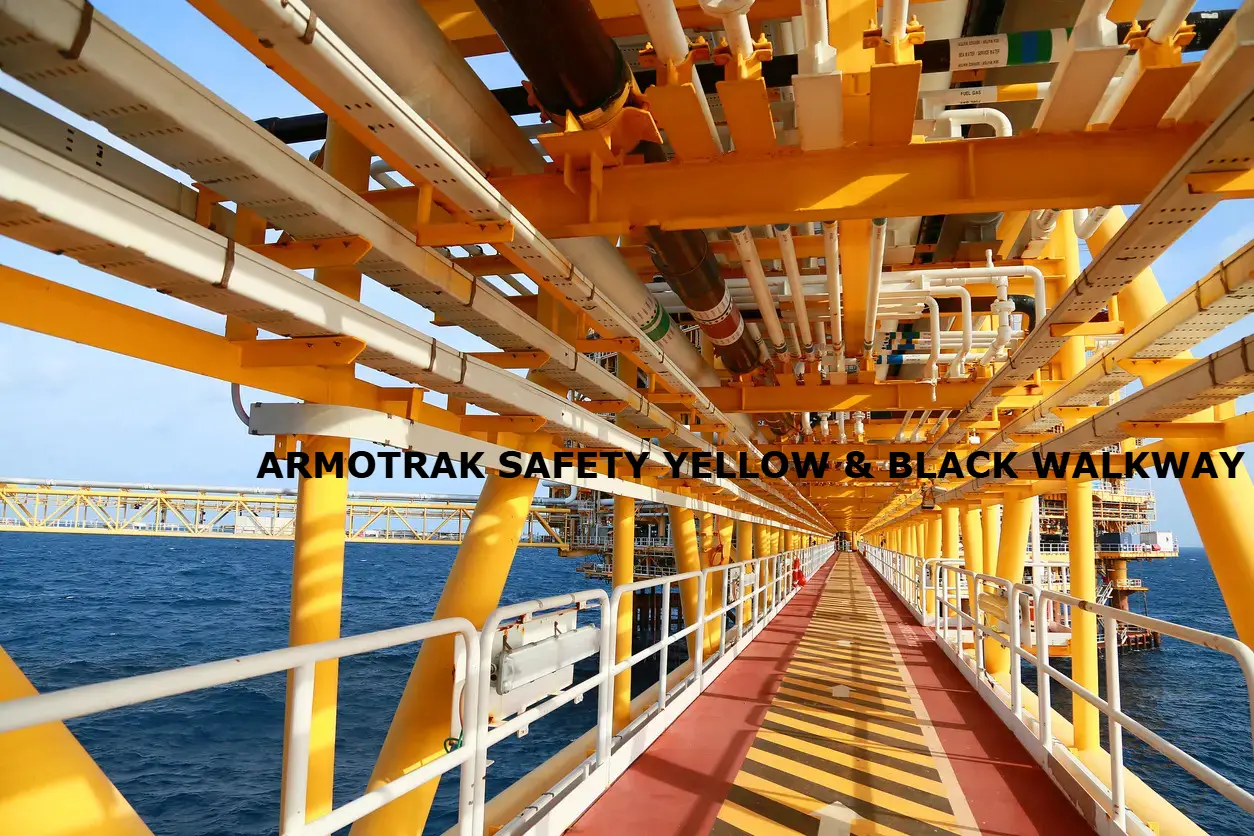

ArmorTrak Rubber Textured Non-Slip Epoxy Coating

Industrial-grade anti-slip coating for any surface - indoor or outdoor

Ultimate Non-Slip Protection

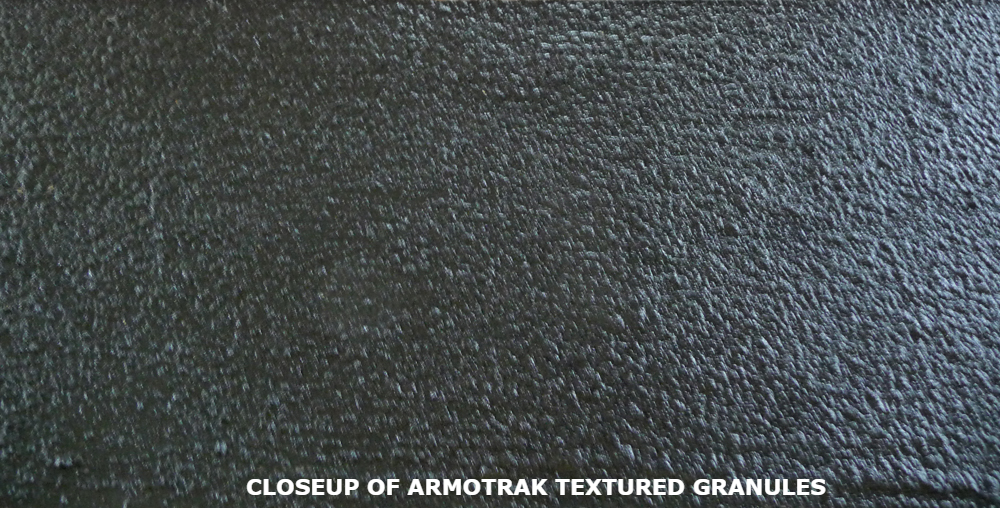

ArmorTrak is a revolutionary rubber-textured epoxy coating that provides superior anti-slip protection on virtually any surface. Unlike traditional coatings, ArmorTrak creates a flexible, durable, rubber-like finish that grips in wet or dry conditions.

Perfect for high-traffic areas where safety is critical: pool decks, steel steps & work platforms, wet industrial environments, and any surface requiring maximum traction.

Superior Durability made with the highest grade of proprietary dehydrated rubber granules that become part of the epoxy when cured. Granules won't wear out of coating as low quality rubber beads in standard rubberized coatings do. ArmorTrak keeps its grip when other coatings go bare and need recoating or a complete removal. Available in safety colors for hazardous areas.

Key Performance Features

Extreme Adhesion

575 PSI bond strength - Concrete surface fails before coating separation. Cannot be pulled off!

Temperature Resistant

-60°F to +200°F range - Works in extreme heat and freezing cold without cracking

Total Flexibility

Rubber-like finish - Flexes with surface movement for a crack-free, long-lasting coating

100% Saltwater Resistant

Marine-grade durability - Perfect for docks, boats, and coastal applications

Thick Protection

35-40 mils dry thickness (2 coats) - Substantial coating that fills imperfections

Fast Application

2-hour working time - Walk on in 12-24 hours, full strength in 48 hours

Technical Specifications

Ideal Applications & Surfaces

ArmorTrak bonds to virtually any surface and creates a rubber-textured, anti-slip finish perfect for:

Perfect for Marine & Pool Applications

100% saltwater resistant and completely waterproof, ArmorTrak is the go-to coating for boat decks, docks, pool decks, and any wet environment. The rubber-textured finish provides secure footing even when soaking wet.

Used by marinas, boat manufacturers, and commercial pool facilities for its unmatched durability and safety performance.

Industrial & Commercial Grade

Extreme abrasion resistance makes ArmorTrak ideal for high-traffic industrial environments. Handles forklift traffic, heavy equipment, and constant foot traffic without wearing down.

The flexible, rubber-like finish absorbs impact and resists chipping - perfect for warehouses, manufacturing facilities, and loading docks.

Unmatched Adhesion Technology

575 PSI bond strength is unprecedented in the coating industry. In adhesion testing, the concrete substrate fails before ArmorTrak separates. Once cured, it cannot be removed without destroying the surface underneath.

This permanent bond ensures your anti-slip coating won't peel, chip, or delaminate - even under the harshest conditions.

Built Once. Done Right.

ArmorTrak can be trusted to perform as advertised ensuring your project's success with long term durability.

Need expert guidance on solutions for your project?

Get custom recommendations and volume pricing.

FArmorTrak can be used for literally hundreds of applications on anything or anywhere a flexible textured coating is required, indoors or outdoors. For vehicle traffic we strongly recommend using black to hide tire marks.

APPLICATION:

ArmorTrak is sold as a per square foot product to ensure you have enough material to complete your project properly.

For all surfaces other than concrete, wood and previously coated surfaces, Bonding Primer must be used first. Wood and previously coated surfaces should be rough sanded clean, concrete surfaces, ceramic and porcelain tiles should be acid etched with muriatic acid in a 3 parts water to 1 part acid ratio and then neutralized with TSP at 1lb/1000 sf. In general all surfaces must be clean and dry prior to application of the ArmorTrak Coating.

Once surface is clean and dry, application is simple. If using the Bonding Primer, stir contents in can till uniform in color. Apply with lint free 3/8” nap roller and let dry overnight. Coverage of primer is 400 sf/gal.

Mix ArmorTrak in can with jiffy mixer in electric drill on medium speed to suspend rubber granules, do not shake can to stir. Apply ArmorTrak first coat with supplied ArmorTrak roller. First coat should go on thin to cover surface. Allow first coat to dry to the touch usually 3-4 hrs. Apply the second coat perpendicular to first coat if possible with the textured ArmorTrak roller. Second coat will get better coverage and should even out the look. ArmorTrak can be applied by brush where coating with roller is not feasible.

Allow to dry overnight prior to foot traffic. ArmorTrak should be allowed to dry for 24hrs before light traffic. Once ArmorTrak has fully cured in 48 hrs it is as tough as nails and will provide many years of service.

PLEASE NOTE THAT THE MINIMUM ORDER SIZE 150 SF AND THEN IN 75 SF INCREMENTS. ORDERS FOR LESS THAN 150 SF WILL NOT BE PROCESSED.