- Description

- Application Instructions

- Features- TDS - SDS

- Comparison Chart

- Supplemental Specs

- Color Chart

Best Commercial Roof Coating for Flat or Pitched Asphalt & Rubber Roofs

Free Shipping Direct To Your Location!

With the lowest moisture transmission rating, Armor Roof Shield is the best roof coating at keeping water out of your building. The only thing more watertight would be a pool liner!

Superior Performance Characteristics: Superior adhesion (cannot be separated from roof material), elongation (500%), memory retention (99.9%), and abrasion ratings (Shore D Hardness-60).

Don't Buy on Price or Name Recognition Alone: This is an often-overlooked mistake made by customers who unknowingly purchase roof coatings without comparing product specifications. Many companies publish little or no specifications due to poor test results.

Expert Guidance Makes the Difference

At ArmorGarage, who you buy from is as important as what you buy. All our Sales Reps have extensive field experience with all the products we sell. We can guide you or your applicator every step of the way so that your project is done right the first time—as opposed to buying roof coatings from someone who never stepped foot on a roof.

Why ArmorGarage Roof Coatings Have Superior Leak-Stopping Capabilities

Vapor Transmission Rating (Permeability): This determines how much moisture can pass through the coating over time. As your roof or coating ages, molecular bonds weaken and pores get larger due to stretching and UV aging—eventually water starts passing through your roofing material or coating.

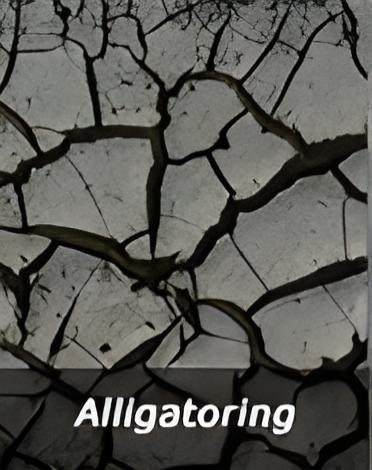

That's why sometimes you can't seem to stop leaks no matter how many flashings, small cracks, or pits you patch. It's because water may be slowly passing through the pores of your roofing material or coating over a large area and then running to the first opening. Finding and patching leaks becomes a costly and futile effort. The majority of roofs start leaking due to this issue—they simply stretch and wear out from UV exposure and the elements.

Start with the lowest permeability rating and highest rubber content possible. As the coating ages and pores start opening from UV degradation and stretching, it will still repel water. If you start with high permeability and low/no rubber content, it takes surprisingly little aging before that coating fails. The type of rubber is also critical—we use Butyl rubber, the highest grade for coatings.

The ArmorGarage Guarantee

ASTM G53-9000 Hour Accelerated Weather Test: Armor Roof Shield has by far the lowest Vapor Transmission rating. When tested during this extreme UV exposure and temperature swing test, it showed NO degradation or loss in permeability!

That's why we offer a 15-year guarantee and no one else can. Some brands offer longer guarantees but state they do not guarantee results, or you can't walk on your roof, or warranty is void if not installed by a professional. Here's the best part: you have to renew your guarantee every 10 years—meaning it costs you every 10 years or you have no guarantee. What kind of guarantee is that?

15-Year Leak-Free Guarantee with No Ifs, Ands, or Buts!

If you cover your entire roof with Armor Roof Shield, it's guaranteed 15 years to keep you leak-free. It flows into every tiny crack, crevice, and pinhole, forming an impenetrable barrier that is super durable and impossible for water to pass through.

The ArmorGarage Difference: Toughest Roof Coating

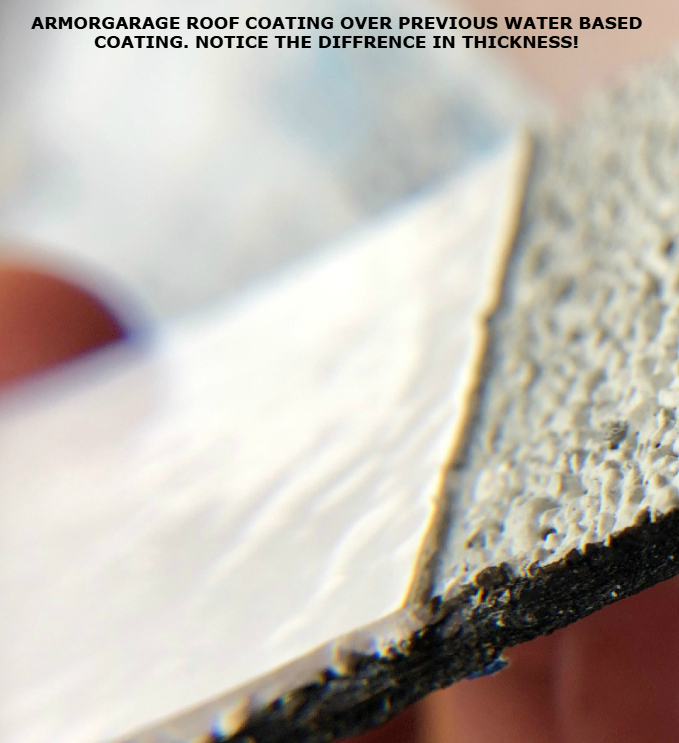

When we say Armor Roof Shield is the toughest roof coating, we mean it! This is our Light Gray Armor Roof Shield in extreme performance testing. Don't try this with water-based elastomeric or silicone coating—the force and abrasion would rip regular roof coatings to shreds.

Military-Proven Performance: Beale Air Force Base

Aerial view of our Metal Roof Coating installed at the Security Building at Beale Air Force Base. It's the same coating modified to compensate for extreme expansion and contractions of metal roofs. There's a reason the Air Force has chosen ArmorGarage for their roofs! You will get the same results and performance for our Tar & Rubber Roof Coating.

Real-World Hail Storm Testimonials

Below is a testimonial from our customer Patricia Jarimillo showing how tough our roof coating really is. Additionally, one of our residential metal roof customers lives in a historic neighborhood that had over 80% of roofs destroyed by a severe hail storm—his roof suffered only minor cosmetic damage. Between our severe weather testing and real-world hail storm testimonials, we're not sure what else we can say.

"Here is our review of ArmorGarage Flat Roof Coating. It's great! This review comes a year after we used your product on our roof so it's more a testament to the quality of your product than merely getting the job done."

"We've had several heavy hail storms and rains and of course, we had to go up and check out the roof. There were no dents, no peeling or lifting of the product, no pooling and no bubbling or stretching. It looked perfect. My husband says, 'That stuff really works.'"

"The Flat Roof coating bonds to the roof and is not merely a latex coating that will eventually peel when water gets under it from a crack, dent or hole produced from hail. It doesn't peel off gloves or boots either. We also noticed right away that the solar coating aspect of the product helped to cool the interior by at least 10-15 degrees. Great product. Our roof size required 22 buckets which we consider an investment."

"Your product is beyond belief. You should see what it accomplished on my rubber roofed trailers, just incredible."

High-Traffic Applications

Rubber Granule Version Available: For roofs with heavy foot traffic—such as roof decks or areas around roof-mounted mechanical equipment. Applied with trowel (or roller if thinned slightly with Xylene). A base coat of standard coating can be applied first, then second coat with granule version on high-wear areas.

Custom Colors Available: Orders of 50 gallons or more.

Application & Warranty Details

- 15-Year Guarantee: Two coats of Armor Roof Coating provides guaranteed leak-free service

- Full Roof Coverage Required: Coating must be applied to entire roof for warranty coverage

- Proper Repairs Required: All flashings and defects must be repaired with ArmorGarage Roof Mastic prior to coating application

- Annual Maintenance Recommended: Remove accumulated debris and ensure roof drains are clear

- Free Shipping: Direct to your location on all orders

Ponding Water Areas: For areas where water ponds longer than 48 hours after rainfall, use our Roof Ponding Water Coating.

Warranty Coverage

Guarantee covers delamination or erosion of coating during warranty period. This is a tried-and-true product that doesn't fail. Each lot is thoroughly tested before shipping to ensure defect-free product. Should you feel the product has failed, notify ArmorGarage by email or fax with description and nature of failure. On substantiation of product defect, ArmorGarage will provide sufficient replacement product to repair all affected areas.

Warranty Exclusions: Failure to apply coating according to instructions, natural disasters and acts of God, shifting/swelling of roofing system or structure, exposure to destructive chemicals, over-accumulation of organic materials/water/debris, failure of previously applied coatings, negligence, misuse, cosmetic changes in coating appearance.

PROJECTS 10,000 SQ FT OR MORE

Request a Quote for Volume DiscountsHow to Apply Flat & Pitched Roof Coating

Complete step-by-step guide for tar, rubber, and flat roofs — clean, prep, mastic, and two coats to a leak-free finish

Coverage Calculator

Coverage is 100 sq ft per gallon and two coats are required. Use these formulas to determine how much product you need:

Real-World Roof Coating: Start to Finish

The following photo series perfectly illustrates how to do a proper roof coating job. Even though these are smaller roofs, the concept is exactly the same no matter how large the roof is: clean the roof, mastic seams and flashings as needed, and roll or spray on two coats.

See the Difference: Notice the roof to the right in the first photo — it has an aluminum fibered roof coating that is failing after only 3 years. That's the reason the owner chose Armor Roof Shield for this leaky roof and all remaining roofs.

Inspect & Clean the Roof

Product is applicable down to 40°F. Temperature must remain above 40°F for a minimum of 24 hours after application. Do not let freeze.

Surface Prep Checklist

- Clean all dirt, debris, and residues from the entire roof surface

- Scrub mold or mildewed areas with a chlorine or bleach solution

- Power wash if possible for best results

- Visually inspect all flashings and seams for debonding, cracks, or pit holes

- Check all roof penetrations — vents, HVAC units, pipes

Important — Check Inside Mechanical Equipment: Water often penetrates the inside of roof-mounted equipment and other flashings, finds its way down to the roof deck, and runs to an opening far from the original leak source.

Repair & Apply Mastic

Patch any damaged areas, visible cracks, punctures, or areas that have completely worn through using our Roof Patch Mastic for best results.

What Needs Mastic

- Seams that have split apart or cracked (tight seams do not need mastic)

- Curb flashings with cracks or pit holes

- All roof penetrations — vents, pipes, HVAC curbs

- Any area with prior patch material — remove as much old residential-grade roof cement as possible, then coat over the rest with our mastic

Ponding Water Areas

- Apply two coats of Roof Mastic to ponding areas

- Embed roofing mesh into the first coat, then apply the second coat over it

- Let mastic dry, then coat with Armor Roof Shield

- Areas that hold water more than 48 hours after last rainfall should be coated with our Ponding Water Roof Coating

Armor Roof Coat is very forgiving — it will cover up many types of small mistakes. But a little extra time and effort in prepping your roof will result in a much higher quality job.

Roof prepped with mastic on all seams and flashings — once the coating was applied, it was impossible for it to leak

Apply the First Coat

Roof Shield requires no special skills or experience. The main objective is to get an even coating over the WHOLE roof. If you do that, Roof Shield will take care of the rest.

Mix the coating in the can with a paddle mixer on low speed. Use a high-quality brush to coat hard-to-reach areas first.

The 500 sq ft Grid Method

On large roofs, after cleaning and prepping, mark out 500 sq ft sections and place a pail in each section. This method makes it easy and foolproof to get the coating applied evenly at the proper spread rate — simply roll or spray one pail per square!

500 sq ft sections marked out — one pail per section for foolproof even coverage

Application Tip: You can use a calibrated squeegee to spread the coating out first — it makes it easier since the coating is so thick that a roller sometimes slides across the top initially. Then back-roll with your roller.

Proceed section by section until the entire roof is coated, maintaining the 100 sq ft per gallon spread rate. Roof Shield can be applied from the roof right up parapet walls.

Apply the Second Coat

Allow the first coat to dry 24–48 hours until dry and hard to the touch, then apply the second coat.

Pro Tip: Apply the second coat perpendicular to the first coat for best results. Make sure to cover every inch of roof surface — as long as you get coating on 100% of the surface, there is no possible way water can leak through.

Flexible Timing: If needed, you can wait several days or even a week or two between coats. The second coat will reactivate the first coat and the two will bond together, curing into a single monolithic rubber surface.

Finished roof after two coats — close to 20 years later and still hasn't needed a recoat

Spray Equipment Specs

Armor Roof Shield cannot be sprayed with light-duty sprayers designed for water-based products. Use a commercial airless sprayer with these specifications:

- 3,300 psi with 0.75–1 GPM minimum

- Tip size: .027–.031

- Hoses: 3/8" ID (use 1/2" ID for hose lengths over 60')

- Recommended: Graco Ultra Max 795 or higher

- Thinning: Depending on sprayer, 4–8 oz of Xylene per 5 gallons may be needed for proper spray pattern

Maintain the 100 sq ft per gallon spread rate regardless of application method.

Rubber Granule Version: Applied by trowel with average coverage of approximately 25 sq ft per gallon. A base coat of the standard coating topped with one coat of the granule version on walkways or around mechanical equipment is acceptable. Always do a test patch first when applying to any type of rubber roof to ensure compatibility.

Weather & Application Conditions

- Do not apply if temperature will fall below 40°F during the curing period

- Do not apply if rain is forecast within 24–36 hours

- Temperature must remain above 40°F for a minimum of 24 hours after application

- Do not let freeze

Questions About Your Roof Project?

Whether you're coating a small flat roof or a 100,000 sq ft commercial building, we're here to help. Our techs have helped customers install millions of square feet of this product.

Talk to an expert at 866-532-3979 — info@armorgarage.com or Request a Quote for project pricing and volume discounts on large roof jobs.

This is a close up of the an area patched with residential grade roof cement or coating. This is typically what happens after just a short time. You must remove as much as possible and then coat over whatever can't be removed with our roof mastic as seen below.

This is the roof prepared with our roof mastic. The owner chose to do all the seams and flashings since the roof was small enough. Normally you would apply our roof mastic to where it's needed only. But this isa good example of prepping any roof. Once the coating was on it was impossible for it to leak and it didn't

This is the finished roof after two coats. The roof is now close to 20 years old and the owner has not had to recoat it. When the time comes all that's needed is a cleaning and roll on one new coat.

APPLICATION:

Product is applicable down to 40 degrees. Temperature must remain above 40 degrees for a minimum of 24 hours after application. Do not let freeze.

SURFACE PREP: Roof must be cleaned of all dirt, debris and residues, scrub any mold or mildewed areas with chlorine or bleach solution. Power wash if possible. Patch any damaged areas, visible cracks, punctures or areas that have completely worn through, use our Roof Patch Mastic for best results. Visually inspect all roof flashings, seams for debonding, all penetrations and repair as needed. Only seams that have split apart or cracked need to be patched, same with curb flashings, only flashings that have cracks or pit holes need to be patched. Embed roof mesh into Roof Patching Mastic for extra strength and flexibility. All ponding areas should be coated with two coats of Roof Mastic, embed layer of roofing mesh in first coat and then apply second coat. Let the mastic dry and then coat with Armor Roof Shield. Any ponding areas that hold water more than 48 hours should be coated with our Ponding Water Roof Coating. Armor Roof Coat is very forgiving as it will cover up many types of small mistakes but a little extra time and effort in prepping your roof will result in a much higher quality job.

APPLICATION: Roof Coat is easily applied by just about anyone and requires no special skills or experience. The main objective is to get an even coating over the WHOLE roof. If you do that, Roof Shield will take care of the rest.

On Large roofs after it has been cleaned and prepped mark out 500 square foot sections as shown in the image below and place a pail in each section. Mix the coating in can with paddle mixer on low speed. Use a high quality brush to coat any hard to reach areas first. This method makes it easy and foolproof to get the coating applied evenly at the proper spread rate. Simply roll or spray one pail per square!

If rolling you can use a calibrated squeegee to spread the coating out, it makes it esier cause the coating is so thick a roller sometimes slides across the top at first. Then backroll with your roller.

Then proceed to next section and repeat until entire roof is coated in the same manner maintaining the 100 SF/Gal spread rate. Roof Shield can be applied from roof right up parapet walls. Allow first coat to dry(24-48hrs)until dry and hard to the touch then apply second coat. For best results apply second coat perpendicular to first coat. If need be you can wait several days or a week or two between coats, the second coat will reactivate the first coat and the two coats will bond and cure into a single monolithic rubber surface. Be sure to cover every inch of roof surface. As long as you get the coating on 100% of the roof surface there is no possible way water can leak through. Tip: Make sure you check the inside of all mechanical equipment and the flashings around all roof penetrations, often water penetrates the inside of roof mounted equipment and other flashings, finds its way down to the roof deck and runs to an opening which could be far away from the original leak source.

Armor Roof Shield cannot be sprayed with light duty sprayers designed for water based products. Use a Commercial Airless Sprayer with 3300 psi, .75-1 gpm minimum with a .027- .031 tip with 3/8" ID hoses. For hose lengths greater than 60' use 1/2" ID hoses. Graco models-Ultra Max 795 or higher. Depending on sprayer thinning with 4-8ozs Xylene per 5 gallons may be needed for proper spray pattern. Maintain the 100 sq ft/gallon spread rate.

Application for rubber granule version is by trowel with average coverage approximately 25 sq ft/gallon. A base coat of the standard coating topped with one coat of the granule version on walkways or around mechanical equipment is acceptable. A test patch should always be done first when applying to any type of rubber roof to ensure compatibility.

Do not apply if rain is forecasted within 24-36 hrs

Armor Roof Shield — Technical Specifications

Used for flat or pitched roofs, all rubber-type roofs, and all asphalt-based roofs. Can also be applied to wood decks and roofs.

Color: White, Light Gray — See Color Chart for Other Roof Coating Colors

Performance Specifications

Surface Compatibility

Compatible with all asphalt-based and rubber-type roofing systems:

- Modified bitumen

- Built-up roofing (BUR)

- Granulated cap sheets

- Tar and gravel

- Torch down

- All rubber-type roofing — does not cause swelling and debonding of rubber sheets from decking as other products do

- Flat or pitched roofs

- Wood decks and roofs

Technical Resources

Ordering & Delivery Notes

Custom Colors: Colors other than White or Light Gray — allow an additional 5–7 days for delivery.

California Orders: Due to EPA regulations, this product is only available in White for all CA orders. A 20% state surcharge is added to the original order total.

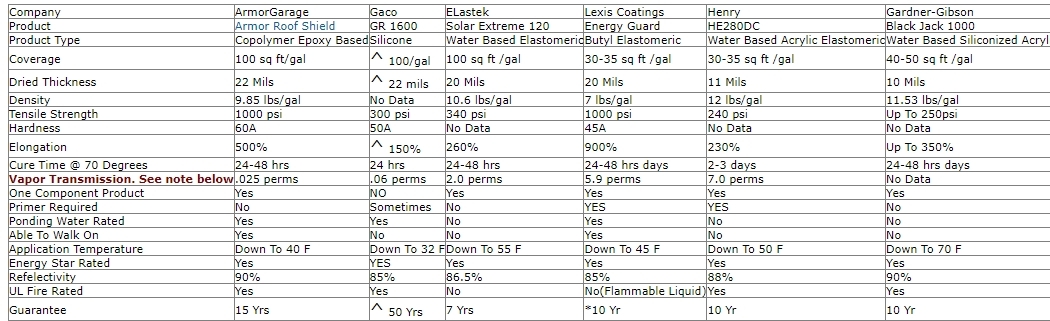

Roof Coating Comparison Chart

Armor Roof Shield vs. popular water-based, elastomeric, and silicone roof coatings — the specs don't lie

Why Armor Roof Shield Is Different

Armor Roof Shield is NOT an elastomeric. It's made with a Copolymer Epoxy Rubber formulation designed to provide a much longer useful life span than lower-cost, retail-grade products.

Retail-grade roof products use water and/or silicone as their main component — much lower-grade materials versus our epoxy rubber base. Water-based and silicone coatings always break down prematurely, regardless of how exaggerated a guarantee may be marketed.

ASTM Verified: Almost no other roof coating company provides ASTM Accelerated Weathering test verification — meaning any claims to longevity are just marketing hype. Armor Roof Shield passes the ASTM 9,000 hour accelerated weathering test with no signs of degradation.

Armor Roof Shield is an industrial-grade coating that can be applied by even first-timers with professional, energy-saving, leak-stopping results that will last. Our coating assures you one of the lowest costs of ownership (cost per years of useful life) over the long term.

Head-to-Head Comparison

Click the chart to enlarge for easier reading

Important Notes on Competing Products

-

Gaco — Coverage & Guarantee Issues

Coverage: On textured surfaces such as all asphalt-based roofs, Gaco requires 3–4 coats. Actual coverage on textured surfaces is only 33 sq ft per gallon — you will need substantially more product.

Guarantee: Gaco does not guarantee their product unless installed by an authorized Gaco installer. Furthermore, Gaco does not guarantee results of application such as stopping leaks. Guarantee is void if the roof coating is walked on or strict maintenance is not performed. Gaco does not provide any ASTM Accelerated Weather Testing to verify longevity. Guarantee is non-transferable.

-

Gaco — Performance Limitations

Tensile Strength: Very low — should not be walked on.

Hardness: A Shore A rating of 50 is exponentially softer than Armor Roof's 60 rating. Armor Roof can be walked on; Gaco cannot.

Elongation: Very low — may be subject to cracking in extreme conditions.

-

Vapor Transmission (Permeability) — The Most Important Factor

The lower the rating, the better the coating resists water and vapor transmission. Armor Roof Coat is four times less permeable than Liquid Roof and multiple times better than the rest.

Simply put, Armor Roof Coat is far superior at preventing water and moisture transmission through your roof. Some coatings have ratings barely below the threshold where moisture will penetrate — just a tiny bit of wear causes them to start leaking.

Note: Black Jack 1000 is not approved for use on flat roofs.

-

Application Temperature & Cure Time

This is the temperature at which a coating stops curing and becomes vulnerable to rain or the curing process not restarting. Until the coating is fully cured, it is vulnerable to being washed away. We receive many calls from customers who had other popular brands just wash right off their roofs.

Additional Notes:

* Guarantee — 10-year only when applied by a certified Lexis applicator.

~ EPDM Coatings, Liquid Roof, and Pro Guard are the same product and therefore have the same specifications.

Ready to Protect Your Roof?

Talk to an expert at 866-532-3979 — info@armorgarage.com or Request a Quote for project pricing and volume discounts.

The following is an explanation of the data you saw in the comparison chart regarding Harness, Tensile Strength and Elongation. It's important that you understand what these numbers mean so you know what level of performance you will be getting. Not knowing these numbers is really buying blind. If you need help in understanding all this data please feel free to give us a call or send us an email.

Hardness: This is an indication of how much wear & tear resistance a coating has, the higher the rating the better. Armor Roof Coat is as tough as nails and has the highest hardness rating. It means it is far more resistant to wear than lower rated coatings. Some coatings void the warranty or require an inspection after you walk on your roof. Any roof coating with a Hardness rating of 50 or lower cannot be walked on without the risk of damage. We recommend using our Granule version around areas that are walked on more than a couple of times a week. Even if you don't walk on your roof you should be concerned about wear. Rain contains lots of particles that it pulls from the air that are very abrasive and corrosive and along with the Sun(UV rays) is what produces that faded worn out look in standard roofs and roof coatings. As you can see Rood Coat has the highest hardness rating, each 5 points in hardness is an exponential difference. Plus we are one of only a few that pass the ASTM 9000 HR Accelerated Weather testing. We strike a great balance between hardness, durability and flexibility making Roof Coat extremely versatile so that it will wear like iron while not cracking or splitting during extreme weather conditions.

Tensile Strength & Elongation are critical factors as to how much Stress, Expansion and Contraction a coating can withstand before failing. Most other coatings are significantly below Armor Roof Coat. In areas with wide seasonal temperature swings most other coatings are very prone to failure. Ames rating is based on use of Polyester Contouring Roof Fabric(additional labor and material costs).

Elongation: Based on ASTM D-412 test tells you how much can the coating stretch before cracking, at 500% we offer plenty of expansion capability and with 99.999% memory retention! Flexibility is no good if the coating doesn't return to its original dimensions. Most coatings will stop returning to their original dimensions after a relatively low amount of expansions and contractions! Then they start leaking because their pores have been stretched past the water repelling point. Then when you look for the source of the leak you will never find it because the the roof is leaky right through the microscopic pores of your bargain roof coating.

Tensile Strength: We have found through extensive testing that 1000psi of tensile strength is needed for a coating to both perform at it's optimum and to be able to survive the high stress demands encountered on roofs. If a coating isn't strong enough it will simply break down and cease to perform. It's that simple.

With commercial roof coatings the saying you get what you pay for is very appropriate. Bargain priced coatings have only one superior feature they offer you cost savings albeit for only a short time until you have to redo your roof cause it's leaking again.