Urethane Epoxy Cement Slurry

1/8" to 1/4" thick industrial flooring system — The M1 Abrams Tank of floor coatings

When You Need A Thicker Floor Than Paint Can Provide

ArmorGarage Urethane Epoxy Cement Slurry is an extra-thick specialized three-component system (epoxy liquids Part A & B plus aggregate) designed for food industry applications where stricter codes or industrial specifications require a minimum 1/8" thickness.

A non-slip, high-gloss, super abrasion-resistant flooring system that endures high impacts, extreme thermal shocks from hot water, steam, and oils. Highly moisture-tolerant, making it ideal for wet and damp areas—can even be applied to damp concrete.

"The M1 Abrams Tank of Flooring" — Among the most advanced coatings available for the food and beverage industry due to its virtual indestructibility.

Ideal Applications

Food & Beverage Facilities

Kitchens, bakeries, food processing plants, breweries, bottling plants

Industrial Environments

Chemical processing plants, wastewater treatment facilities, heavy forklift traffic areas

Sanitizing & Wash Areas

Locations requiring durable, shock and impact-resistant surfaces with constant moisture

Code Compliance

Meets city and state health department requirements for minimum 1/8" thickness flooring

Use this when standard epoxy coatings don't meet thickness requirements. Can be applied from 1/8" up to 1/4" thick!

Simple Installation Process

No prior experience needed! Easy DIY installation with basic tools:

Step 1: Mix liquids A & B with proprietary silica powder using a power mixing tool (compatible with standard drill)

Step 2: Pour onto floor and spread with adjustable Cam Rake at desired thickness (available at Grainger and other stores)

Step 3: Backroll with spike roller (also available at Grainger) to release trapped air bubbles

Curing time: 10-18 hours depending on temperature, humidity, and application thickness. Light foot traffic in 12 hours.

Tools not included: Power mixing tool, Cam Rake, spike roller, spike soles (strongly recommended). See Related Products section.

Watch how easily it spreads with gauge rake and pin roller

Recommended Finish System

For optimal performance and texture, we recommend:

1. Full Broadcast: Apply full broadcast of sand or heavy aluminum oxide to provide textured non-slip finish

2. Topcoat Options:

- Commercial Grade Two-Part Topcoat: Standard applications

- Chemical & Acid-Resistant Topcoat: Areas with caustic washdowns

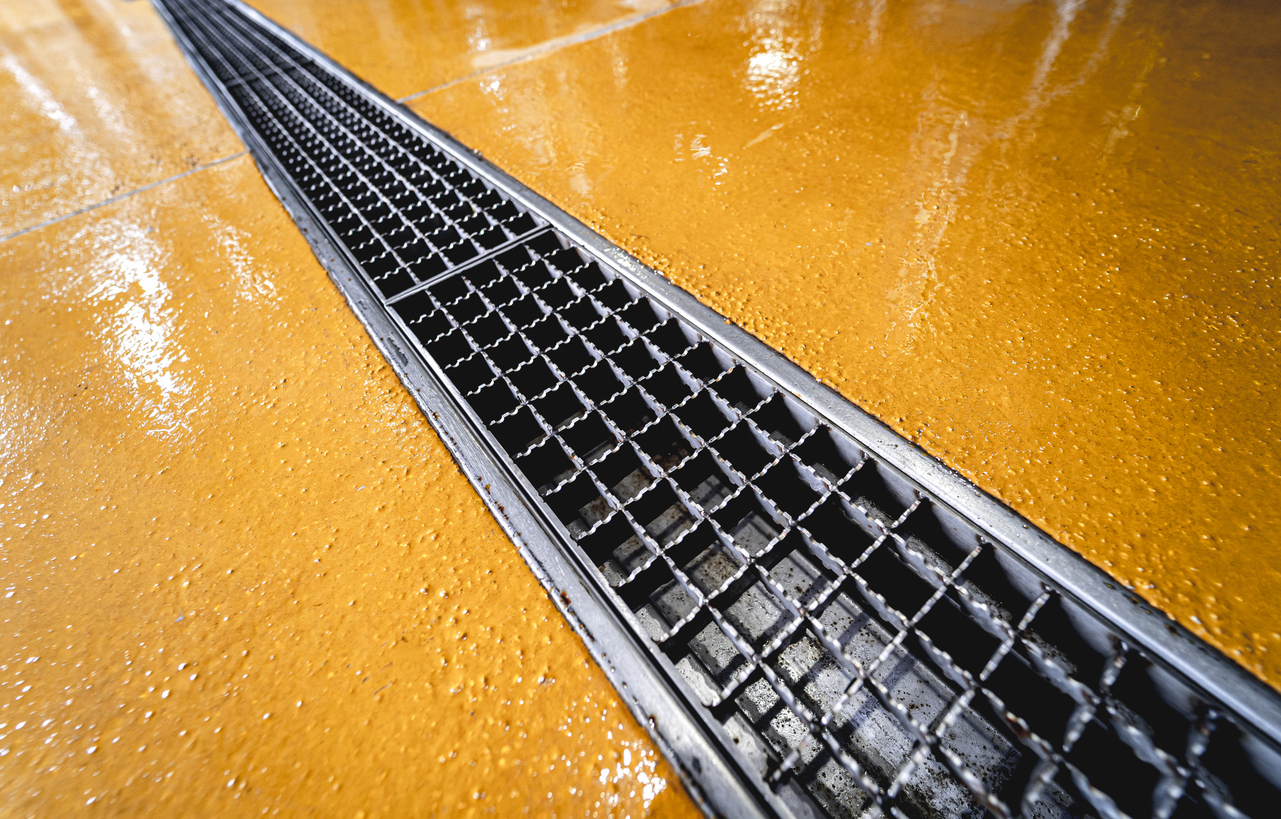

Example: Below is urethane cement with full broadcast sand and commercial two-part topcoat in Safety Yellow around a brewery trench drain. Unlike trowelled quartz systems that need expensive expert installation and multiple coats of "Sealant" with non-slip additive that wears out needing reapplication of Sealant and non-slip additive ArmorGarage's system provides a permanent nonslip finish.

Coverage & Technical Specifications

COVERAGE

@ 1/8" thickness per 50-lb kit

THICKNESS

Self-leveling application

STRENGTH

2x stronger than concrete

Self-leveling and easy to install—excellent choice for resurfacing or coating damaged, pocked, and spalled floors. Cannot be compared to commercial-grade leveling slurries that fail under high traffic.

Available colors: Medium Gray, Tan, or Tile Red. Can be topcoated with ArmorGarage Military Grade Protective Topcoat to achieve any standard or custom color (minimums may apply).

Important: Proper adhesion requires shot blasting or rough diamond grinding for surface preparation.

Additional Performance Benefits

- Chemical Resistance: Resistant to harsh chemicals including acids, alkalis, and aggressive cleaning agents—suitable for the most challenging environments

- Enhanced Slip Resistance: Superior traction when aggregates are broadcast within the system

- Low Odor & Low VOC: Suitable for use in areas with limited ventilation or where air quality is crucial

- Fast Return to Service: Floor can be returned to light foot traffic within 12 hours—convenient for businesses that can't afford long downtime

- Extreme Impact Resistance: Hammer impact resistant, suitable where heavy objects may fall onto the floor—as bulletproof as flooring gets

- Forklift Traffic Rated: Designed for heavy industrial equipment and constant traffic

- Thermal Shock Resistant: Withstands extreme temperature changes from hot water, steam, and oils

- Moisture Tolerant: Can be applied to damp concrete—ideal for wet processing areas

Volume Discounts Available

Contact our office for bulk purchase pricing and project quotes.

Call 866-532-3979 or email info@armorgarage.com