-

METAL ROOF COATING

$430.00 - $490.00 -

-

-

ARMOR SHINGLE ROOF COATING

$369.00 -

Coating For Foam Roofs

$175.00 -

ROOF REPAIR MASTIC

$140.00 -

Roof Coatings for Any Roof Type

ArmorGarage Roof Shield is a high-performance epoxy rubber roof coating for flat or pitched roofs that outperforms traditional elastomeric coatings, tar, EPDM roofing materials, liquid EPDM, and water- or silicone-based coatings.

Finding and repairing roof leaks is more often than not an expensive, futile effort that ends up costing far more than had you encapsulated your entire roof with an ArmorGarage coating from the start. Once fully coated, it's impossible for water to penetrate.

Air Force Base Approved: There's a reason Beale Air Force Base switched from a popular silicone coating to our Metal Roof Coating—performance and durability that competing products couldn't deliver.

Why Our Roof Coatings Outperform the Competition

Look at the difference in thickness between our coating and typical roof coatings. That's the image below—and it tells the whole story. Our coating is made with the highest grade of rubber fortified with military-grade epoxy. Applying ArmorGarage is like installing a new roof that outperforms your original roofing material.

When you start with a thin coating that has a chemical structure with wide pores, it doesn't take much for water to pass right through. ArmorGarage roof coatings have the lowest permeability ratings—meaning the tightest chemical structure with the smallest pores—resulting in superior leak-stopping and prevention capabilities.

9000 Severe Weather Tested: Every ArmorGarage roof coating goes through our 9000 severe weather test to ensure your roof can handle any weather conditions—hail, UV, temperature extremes, and driving rain.

Asphalt Flat Roof Coating

Our Tar and Rubber Roof Coating is perfect for flat or pitched roofs. Applied in two coats at 100 sf/gal, it's an industrial-grade coating engineered to last 15–20 years. With superior stretch and memory retention, the lowest permeability rating, and hail-resistant toughness, this is the best commercial roof coating on the market.

Real-World Results: This large warehouse was full of leaks, causing major headaches for the tenant and owner. ArmorGarage roof coating solved the leak issue and reduced the interior temperature by 7 degrees.

Can be rolled or sprayed on by anyone. Let one of our roofing experts evaluate your roof and provide you with a detailed quote. Volume discounts available.

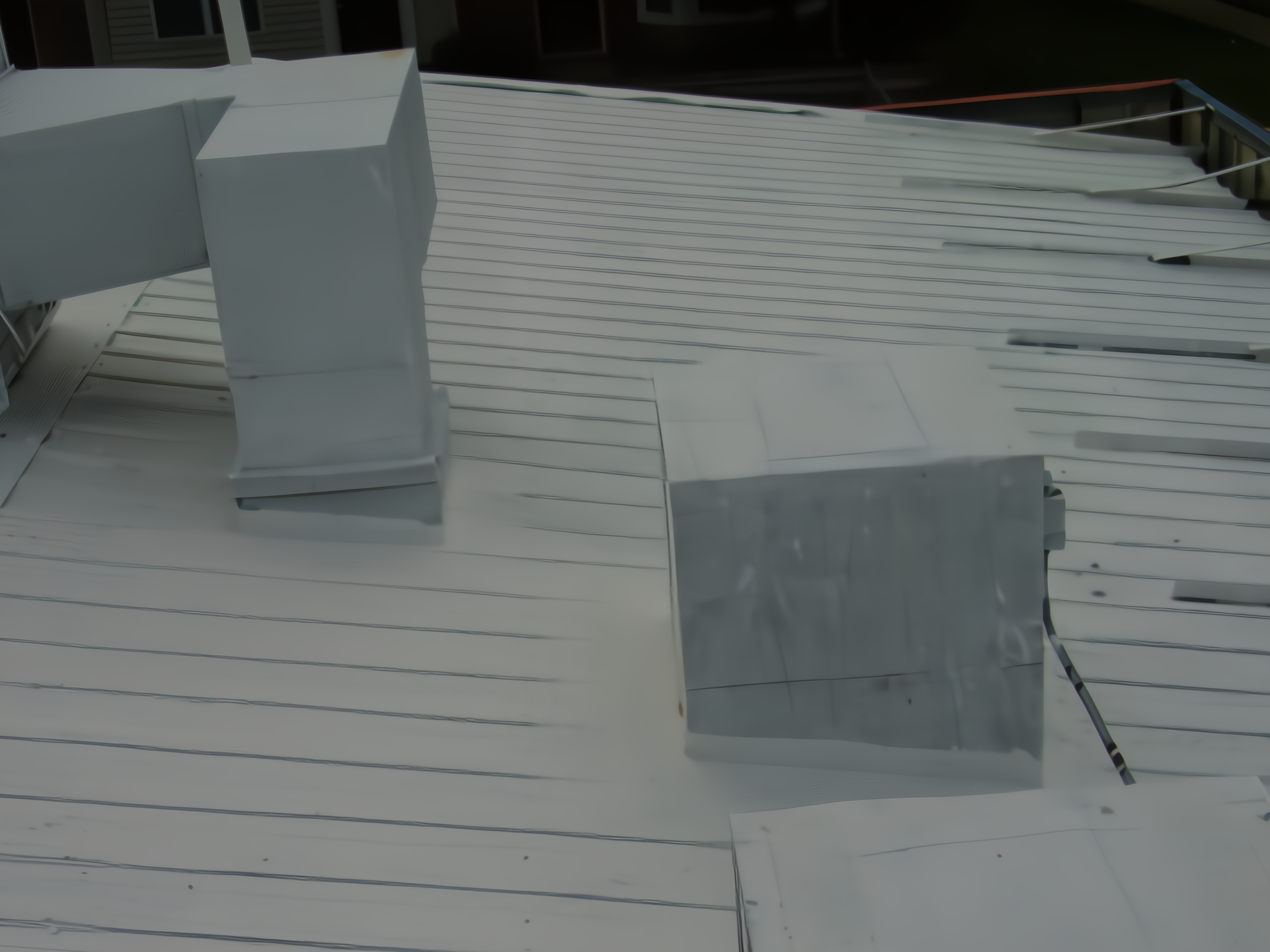

Metal Roof Coating: Before & After

This roof was a total disaster, along with the rooftop ductwork. The building leaked like a sieve and looked like everything needed to be replaced. But one coat of our zinc primer and two coats of the Metal Roof Coating made the roof look brand new.

The ductwork was saved with one coat of our heavy-duty metal epoxy mastic and the protective topcoat. Not only are they leak-free now, but the interior temperature dropped by a whopping 10 degrees during summer months.

Don't Wait Until It's This Bad: We strongly recommend coating your roof before it deteriorates to this level. But if we can achieve this transformation for this customer, imagine what we can do for yours. On the Metal Roof Coating product page, you'll find project images and videos from installations at Beale Air Force Base.

They were using a popular silicone roof coating until they got tired of its underperformance and useless warranty. After switching to ArmorGarage, they couldn't be happier—and we matched the coating to their custom color so the roofs blended into the background rather than appearing bright white.

Left: Before — deteriorated and leaking | Right: After — restored and leak-free

Asphalt Shingle Roof Coating

ArmorGarage asphalt shingle roof coating is one of the best-selling and best-performing coatings you can apply to your shingled roof. Many popular coatings don't allow your shingles to breathe, risking rot damage to your beams and boards. They also get burned off quickly from intense sun exposure, leaving shingles unprotected.

- Locks Down Granules: Once shingles lose their granules, it's too late—this coating preserves them

- Stops Leaks: Seals and protects aging shingles from water penetration

- Rejuvenates Color: Restores faded shingle appearance

- Extends Roof Life 5–7+ Years: Delays costly full replacement

- Easy to Apply: Roll on or use a simple garden hand pump sprayer

Ponding Water Roof Coating

Flat roofs are notorious for low spots where water accumulates and sits for two or more days. It's extremely destructive to any asphalt-based roof, including torch-down and built-up systems. Low areas accumulate silt and debris when standing water finally evaporates.

Purpose-Built for Standing Water: You must apply a coating specifically designed for ponding conditions. ArmorGarage's ponding water coating thrives underwater, is recoatable (unlike many silicone products), and is durable enough to be walked on—unlike competing coatings.

See the Ponding Roof Coating product page for detailed examples of silt buildup and application instructions.

The Real Cost of Temporary Roof Fixes

Patching leaks with cheap, low-quality products creates an expensive cycle: the leaks stop temporarily, then return. You repair again and again until you're facing complete roof replacement—having spent a fortune on "inexpensive" products that created a bigger problem than you started with.

The Critical Question: Many coatings can stop a leak—spray cans exist for this purpose. But the real question isn't can it stop leaks, it's how long will it keep them stopped?

ArmorGarage Roof Coating stops leaks with one application and keeps you dry for a minimum of 15 years guaranteed, with an average lifespan of 20 years. That delivers one of the lowest costs of ownership in the industry—product cost divided by years of actual service.

Silicone Warning: If you used 100% silicone, you're stuck with that product because nothing else will adhere to it. Be extra careful with "50-year warranty" claims—most require renewals every 10 years. Beale Air Force Base learned this the hard way before switching to ArmorGarage exclusively.

Why Armor Roof Shield Outperforms Every Competitor

Armor Roof Shield contains zero water content and maintains a failure-free track record since its introduction. The difference is immediately visible: our coating offers tremendous thickness compared to popular water-based brands that lose over half their volume to water evaporation during curing. Using ArmorGarage is like adding another layer of roofing material—while other brands simply paint your roof with a thin film.

Superior Materials & Proven Technology

Since 1988, we've helped customers who couldn't find a product that was easy to apply, guaranteed long-term durability, and cost less than roof replacement. Armor Roof Shield combines our extensive epoxy technology with a copolymer butyl rubber base—the highest grade available and far superior to EPDM alternatives.

EPDM Spec Warning: Be careful when comparing specs for EPDM-type coatings. Many manufacturers state specs for actual EPDM rubber material, which are not the same as liquid EPDM coatings. Armor Roof Shield outperforms both aftermarket liquid EPDM coatings and actual EPDM sheet material.

Trusted Nationwide: Specified by architects, engineers, and professionals. Used by all branches of the US Military including the Coast Guard, Fortune 500 companies, and commercial property owners across the country. Manufactured in the USA with free shipping on all US orders.

Talk to a Roofing Expert

Not sure which coating is right for your roof? Contact us with pictures and videos of your roof for expert advice on which product to use and how best to apply it. We have many years of field experience with roof projects of every size.

Ready to Get Started? Talk to an expert at 866-532-3979 — info@armorgarage.com or Request a Quote for project pricing and volume discounts.

What Our Customers Are Saying

"Good explanation of products and how they should be applied. Website easy to navigate. You get what you pay for!"

— Timothy I. | February 2026

"Best products for flat roof with ponding issues."

Roof Coatings FAQ

How long do ArmorGarage roof coatings last?

Are volume discounts available for large roofs?

You can even send us pictures and videos of your roof for expert advice on which product to use and how best to apply it.

What roof types can be coated?

Can I apply a roof coating myself?

Do roof coatings help reduce heat?

How long does it take to coat a roof?

Sprayers increase productivity on larger and metal roofs. Many large commercial roofs can be sprayed in a single day and completed the next day for the second coat. Allow sufficient time for cleaning and for the roof to dry prior to starting application.

What about roof penetrations and seams?

Metal roofs: Repair split seams with mastic and roof mesh, check all screws for tightness, and either coat screw heads with mastic or replace with oversized roof screws if stripped.

Tar and rubber roofs: On smaller roofs, it's just as easy to coat all seams and flashings with mastic. See the Mastic product page for detailed prep instructions.

Shingle roofs: Use any paintable caulk to fill visible holes or cracks. On any roof type, do not use silicone-based products—they are not recoatable, even if they claim to be.

Proper cleaning and roof prep are key to a successful, long-lasting project. Speak to an ArmorGarage rep about your roof's condition and how best to prepare it.

Can I coat over a previous patch or coating?

If you're unsure about a previous coating, ask us for a sample to do a test spot and ensure product compatibility.

Do I have to prime my roof?

Do I need to clean the roof first?

Shingle roofs: Use a garden hose sprayer and TSP solution. TSP is a good all-around cleaner for all roof types. Use a mold and mildew remover or bleach mixture where needed, and rinse thoroughly.

Ponding water areas: You'll find large soot and silt buildup. Remove all of it down to the roof surface, then clean with mold and mildew remover or bleach to kill any organic growth. Spot coat these areas with the Ponding Water Roof Coating.

In general, all roofs must be clean, free of all mold, mildew, soot, and silt, and be 100% dry before coating.

The Facts About Stopping Roof Leaks

Armor Roof Shield provides commercial property owners and facility managers with an affordable,

guaranteed long-term solution to chronic roof problems.

Long-Lasting Performance That Saves Money

Many rubber roof coatings can stop a leak—spray cans exist for this purpose. But the critical question isn't can it stop leaks, but how long will it keep them stopped?

Our Coatings stop leaks with one application and keeps you dry for a minimum of 12-15 years guaranteed, with an average lifespan of 20 years. This delivers one of the lowest costs of ownership—product cost divided by years of service.

Would you rather have a higher first cost or a lower repeating cost that ends up more expensive in money, time, headaches, lost productivity, and eventual roof replacement?

Superior Materials & Proven Technology

Since 1988, we've helped customers who couldn't find a product that was easy to apply, guaranteed long-term durability, and cost less than roof replacement.

Armor Roof Shield combines our extensive epoxy technology with a copolymer butyl rubber base. Butyl rubber is the highest grade available—far superior to alternatives like EPDM—resulting in performance characteristics other coatings simply can't achieve.

Water-based elastomerics, silicone, and aluminum-fibered roof coatings generally have poor performance specifications that translate to subpar real-world results, regardless of their guarantees.